Designed to work with any groove-style screen media panel, Haver & Boecker Niagara’s Cap & Slide deck frame offers the same ease of installation and extended wear life as its Pin & Anchor design. The system features 8-in.-long polyurethane sections that cover the top and sides of the rail, providing a barrier against abrasion and corrosion, the company says. The sleeve locks into the rail and is held in place with a polyurethane key. As individual sections show wear, they can be removed and replaced in small sections rather than changing the entire deck frame.

A solution to address issues experienced with synthetics

With its modular PFX/HT hybrid screening panel, Buffalo Wire Works aims to address open area, heavy loading and throughput issues that all-synthetic screen systems cause. According to Buffalo Wire Works, its hybrid screening panel achieves this by embedding high-efficiency, self-cleaning screen technology into a polyurethane frame system. No deck modification is required, the company says, and the panel is ideal for heavy-duty applications. The self-cleaning vibrating wire utilizes profile wire technology to maximize strength, accommodate heavier loads and allow for extreme open area. The design allows for improved wear life, Buffalo Wire Works adds, as the vibrating wire naturally absorbs and dissipates energy more efficiently than traditional systems.

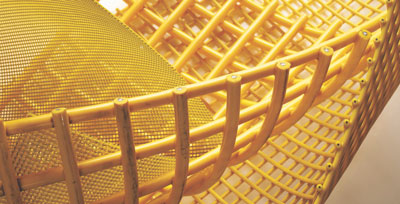

Cast urethane products decrease downtime, maintenance

Rhino Hyde’s Rhino Grid cast urethane products aim to deliver superior wear properties across multiple screening lines. The products were tested in a number of applications, the company says, providing extended run time and reduced maintenance. Rhino Grid cast urethane has a higher capacity to resist rubbing or scraping during production, the company adds, outlasting materials such as rubber, plastics and metals and making it an ideal solution for high-impact or repeated impingement applications. The products are designed to reduce downtime and take the pressure off maintenance crews by lasting seven to 10 times longer than alternative applications, Rhino Hyde says. The products are available as side- or end-tension screens.

Self-cleaning media with molded rubber strips

Livewire from Durex Products features molded rubber strips that hold high-strength wires in place. Providing better screening action than traditional woven wire and greater open area than polyurethane, Durex says Livewire reduces blinding and pegging problems while delivering superior wear life. Livewire is available in XT high-tensile or stainless steel wires. According to Durex, its wire specifications provide ideal durability and strength that allow for the use of lighter-gauge wire, resulting in more openings per square foot. Rubber strips provide superior flexing action for self-cleaning, the company adds, delivering greater wear life in conditions that may adversely affect polyurethane.

Combined wire, urethane screen enhances production

Unified Screening & Crushing’s SuperFlow woven wire screen media helps producers achieve less downtime from screen changeouts, consistency in sizing, and lower costs per ton. SuperFlow, a self-cleaning screen with a combination of wire and urethane, offers flexibility and longer wear life, handles damp and sticky material, and greatly reduces plugging and blinding while maintaining accurate sizing, the company adds.

Combining the best of wire cloth, polyurethane

Sharkskin is a screen media that combines the open area of woven wire cloth with the wear life of polyurethane. According to Hoyt Wire Cloth, Sharkskin’s design makes it light, flexible and easy to install. Sharkskin is a cost-effective solution for a variety of difficult applications, the company adds. The screens can be rolled and carried by one person. Other benefits are reduced near-size plugging and noise abatement. Hoyt says Sharkskin is ideal for smaller decks where open area loss won’t allow for the use of modular screen media.

Added open area with more effective cleaning

Metaldex Ultraclean features design upgrades that provide 9.5 percent more open area compared to similar modular wire panels, according to Polydeck. The design allows the product to deliver more effective cleaning and accurate sizing, the company adds. Designed to push the boundaries of open area in modular wire products, Polydeck says Metaldex Ultraclean is best used in dry, fine-sizing applications or when positioned at the discharge end of screen decks to eliminate blinding or plugging for increased efficiency.