Durex Products

Approaches to effectively maintain screening equipment

Tips to best utilize your operation’s screen media and keep equipment up and running. Keep Reading

Nelson promoted to sales VP at Durex Products

Keegan Nelson, who joined Durex Products earlier this year, previously held roles at Martin Marietta. Keep Reading

Durex Products names business development manager

Tate Sutton, a 16-year veteran of the ready-mix industry, is joining Durex Products' urethane liners, wear parts and accessories division. Keep Reading

The latest in screen media offerings

Take a look at the latest screen media advancements from Buffalo Wire Works, Durex Products, Haver & Boecker Niagara, Hoyt Wire Cloth, Polydeck, Rhino Hyde and Unified Screening & Crushing. Keep Reading

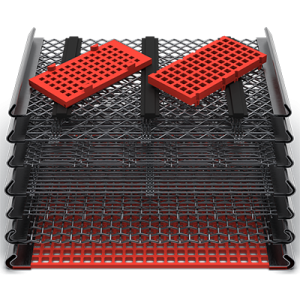

Durex Products Inc. Screen Media, Liners, Wear Parts, Screen Accessories

Durex Products offers a complete line of screen media, liners, wear parts, and screen accessories that help producers fine-tune production and increase tons-per-hour, while keeping products in spec and lowering operating costs. Screen Media Modular Urethane and Rubber — Available… Keep Reading

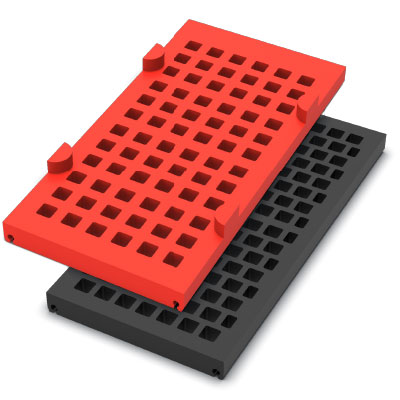

Durex Products, Inc. Modular Urethane and Rubber Screen Panels

Durex Products offers a complete line of modular urethane and rubber screen panels that are easy to install and provide long wear life and elasticity in wet or dry conditions. Durex’s modular urethane and rubber panels feature tapered openings that… Keep Reading

Durex Products, Inc. Wear-Resistant Parts

Durex Products offers wear-part solutions that provide long-term protection for aggregate equipment. Urethane wear parts deliver outstanding efficiency and wear life in even the harshest conditions. They are cost-effective and will combat impact, abrasion, noise, and sticking — in wet… Keep Reading

Durex Products Livewire Screens

Durex Products’ Livewire screen media is a hybrid-type screen, featuring molded rubber strips that hold high-strength wires in place. Keep Reading

Durex Products Accuslot, Vibraspan

Accuslot screens provide the accuracy of square openings with the production efficiency and cleaning ability of long slot wire cloth — helping to reduce plugging and/or blinding, while minimizing the passing of slivers and chips. Keep Reading