Durex Products plans to display its screen media, liners, wear parts and screen accessories at AGG1 (Booth 1147). Among the items Durex will highlight are:

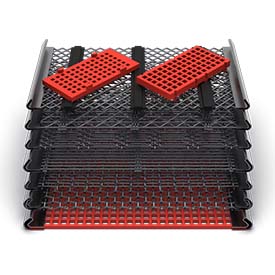

• Modular urethane and rubber screen panels. These are available in modular snap-in, pin-style, knock-in and bolt-in systems. The panels feature tapered openings that are wider at the bottom, reducing plugging and increasing throughput.

• Woven and slotted wire screens. These are made of oil-tempered, stainless or high-carbon steel. Woven-wire screens allow for the use of lighter-gauge wire while providing excellent wear life, Durex says. Long-slot, triple-shoot screens are crimped to provide better screening accuracy and eliminate blinding and plugging.

• Livewire screens. Livewire is a self-cleaning type of screen that features molded rubber strips, holding high-strength wires in place and providing better screening action and greater open area.

• Accuslot screens. These are a self-cleaning type of screen that helps eliminate plugging and blinding while minimizing the passing of slivers and chips.

• Vibraspan screens. Vibraspan is a self-cleaning type of screen featuring longitudinal slots for more open area, without sacrificing product size control.

• Armor screens. These feature a combination of high-grade woven-wire cloth with molded polyurethane coating. They’re designed to increase throughput and reduce plugging and noise.

• Wear liners. Magnetic, plug-weldable and bolt-on liners for screen boxes, crusher mainframes, feed boxes, chutes, flumes and discharge openings are among the company’s offerings.

• Wear parts. These include urethane and rubber used in sizing and separating on screens, classifiers, dewatering screws and various chutes and transfer areas.

• Screen accessories. Accessories include, but are not limited to, side-tension rails, J-bolts, U-bolts, donuts, stringers and ferrules.