The wireline geophysics terminology Mike Dorsey so easily discusses may not be familiar to members of the aggregate industry – yet. This advancing technology has been used with boreholes in oil and water wells for several years to assess rock formation and the expanse and value of a well.

Dorsey, production supervisor at Tilcon New York Inc., was introduced to wireline geophysics as he completed his geology degree. It’s been several years since he started researching the potential for use of geophysics to help evaluate rock quarries and perhaps project reserve potential.

“I was amazed at the amount of geological and hydrological information extracted from a borehole by me and my college research team,” Dorsey says. “Introduction to the technology made me wonder how it could be used to explore other complex structures.”

For several years, Dorsey has researched what types of inexpensive imaging software could be used to obtain geophysics data. After much trial and error, he’s pieced together both a collection of useful software and a method for gathering and analyzing captured data.

Structure from Motion (SfM) is cheap and powerful,” Dorsey says. “It quickly captures a wealth of data through photos taken on a phone camera.”

SfM builds 3-D models using images of a feature that were taken from different angles around and even above the feature. Photogrammetry principles – the study of making measurements from photographs – is part of the analysis process. SfM is much simpler and requires less expensive equipment than LiDAR.

In the SfM process, photos are submitted to the software and the program produces a set of 3-D points that is a model of the feature photographed. Through a series of steps, users create a 3-D image of the feature.

“For a more complete model, the photos must overlap and provide different views of the subject,” Dorsey says. “Movement while capturing the photos is key, thus the name. After the photos are uploaded to the computer, SfM software uses the movement of the different viewpoints to create a 3-D model.”

Put to the test

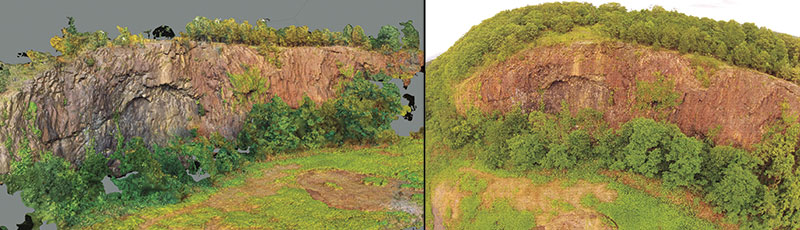

Dorsey has conducted three experiments to explore SfM features and capabilities. He completed his first experiment at a large outcrop of the Palisades Sill in Gurnee County Park, New York. He photographed the sill, Jurassic in age, using an iPhone camera, walking the length of the exposure. All photos were processed in Agisoft and successfully combined to create a 3-D model.

“The most time-consuming piece of the experiment was in processing photos,” Dorsey says. “In larger areas, drones or small aircraft would more quickly capture the necessary photos. The value of this experiment lies in the fact that a scale model of a mine site can be used to plan future mine development or calculate reserves.”

Dorsey’s second project was to test slope stability and movement, using SfM. Since he wanted to control the outcome of the experiment, he used a pile of mulch as a pseudo-slope rather than a slope that would naturally move.

“I set up a stationary datum in three locations to monitor slope movement,” Dorsey says. “These points wouldn’t move throughout the test. Next, a series of photos were taken to generate a mesh of the undisturbed slope face.”

Dorsey induced a small landslide in the pile by removing material from the toe of the slope before photographing the pile again to generate a new mesh.

“In Cloud Compare software I layered the before and after meshes atop each other to analyze the change in both,” Dorsey says. “This is a process that can save lives in a situation where miners working in areas where slope stability is an issue can use this method to test for the earth’s movement.”

Dorsey’s experiment involved fabricated parts, since ordering specialty parts fabricated for specific crushers and other pieces of mining equipment can pose challenges.

“By using SfM to fabricate the parts, fabrication errors can be avoided,” Dorsey says. “I chose to model a section of the wheel assembly of a 4000-class 4-8-8-4 Big Boy locomotive. This model took the longest to generate, but it was easy to capture photos in the field. The finished results were extremely accurate. To further test the accuracy of the model, I printed a section on a 3-D printer.”

Low-cost advances

Dorsey emphasizes that all of the work he’s done can be accomplished on a standard computer with the use of any basic photographic device, even a phone camera.

“Some of the software I’ve used, including SfM, is available in a free trial form,” he says. “None of it is cost prohibitive. For the software I’ve used in these exercises, if you purchased all of them the cost would be around $170.”

Among the tips Dorsey gives for capturing images of the site to be measured: He encourages use of material such as old conveyor belting placed along the site to aid in determining site measurements.

At the drawing table

Some of the ways Dorsey believes the technology and methods can be used include development of a scale quarry model that might provide additional insight to mine managers and planners. With increasing availability of 3-D printers, virtual models could become physical models used for numerous quarry activities.

“Holding a scale model in your hand may be much more effective than viewing it on a computer or a piece of paper,” Dorsey says. “Small components of a model might also be valuable in mining activities and planning. I think the next step in use of this software and method is development of a way to calculate volume in a site. Use of this technology may also reveal site characteristics that aren’t observable any other way, such as sandstone overlying a desired rock product.”

Dorsey expects a great deal more work needs to be done to develop methods to compare the accuracy of the virtual or scale models, identify mathematical calculations pertinent to the needs of mining managers and brainstorm about how information the software provides can be used to enhance mining activities.

Dorsey is making his research and findings public because he wants to help others searching for similar or same findings to have access to what he’s learned. He also knows combining the efforts of other researchers could expedite discovery of valuable processes.

“All of the software and equipment is low cost, easy to come by and a basic online walk-through tutorial will help users learn the software features,” Dorsey says. “The more brains working on it, the more answers we’ll find.”

Dorsey believes his slope movement study may have the greatest impact on the mining industry because it could save lives. His other two experiments proved large and small scans of a location or object create an accurate model that can provide insight into mine planning or parts fabrication.

“I believe this software holds great potential for many different applications, both within and outside the mining industry,” Dorsey says. “I look forward to seeing what other interested people come up with and what thoughts and ideas they have to contribute.”

Loretta Sorensen is a freelance writer in Yankton, South Dakota. She produces material on a variety of topics, serves as a ghostwriter, and has authored her own books.