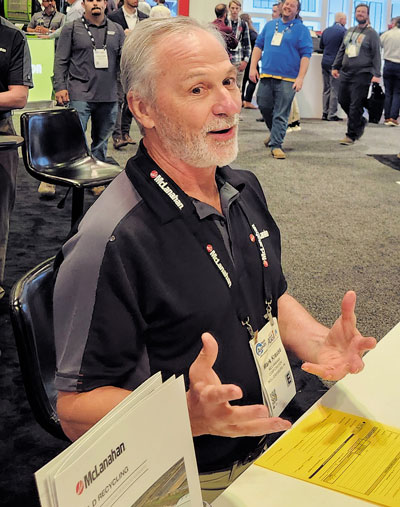

During an AGG1 press conference, McLanahan’s Mark Krause discussed the trajectory of construction and demolition (C&D) recycling in North America.

C&D recycling has long been prevalent in Europe, Krause says, but it’s gaining momentum in the U.S. and Canada. McLanahan is among the equipment manufacturers entrenched in this developing space.

“We’re seeing this everywhere,” Krause says. “I think it’s because of the economics. [We’re] seeing this in the West, Texas, in the East and in different geologies. Even right around here (Nashville) … we’re seeing demand and requests for it.”

Aggregate producers are among those venturing into C&D recycling, he adds.

“If you think about the companies over in Europe – the Heidelbergs (formerly Hanson), Holcim, Lafarge, CRH – [they] have been doing it over there for 10 years,” Krause says. “So, it’s pretty easy for them to bring that over here.”

Additionally, Krause says the equipment involved isn’t all that different than what’s typically used to process virgin aggregates.

“We’ve got a screener here that’s going to scalp, and [we] have oversize that goes to a jaw – much like we’ve been doing for 40 years,” Krause says. “We’re processing recycle with a jaw and a cone. We have [a] logwasher and we’re scrubbing. It’s stuff that we’ve done forever.

“We’re separating material out on a traditional screen,” he adds. “Part of it goes to the sand plant. We also might be removing lignite, organics [or] whatever might be in there. We’re recycling water in the thickener. We also then have the filter press to help recycle water.”

Ultimately, Krause sees C&D recycling in the U.S. as supplementing aggregate processing – not replacing it.

“If you look at Europe where everything is kind of smaller – plants are smaller, sites are smaller – I’d see that (recycling) as a necessity there, and it’s probably going to replace,” he says. “But here, I think it’s more [supplemental] because of the scale of what we do. But, again, regulations might change that.

“If you get mix design to where you can actually take the fines out of this and put it into a highway job out here, that’d be one thing,” he adds. “It might be foundations, it might be driveways. [If] you get to where you’re building foundations for homes or roads from the material out of these recycle plants, it’ll drive it a lot faster.”

Developments in tires

Separately, BKT displayed radial tires from its Earthmax range at AGG1.

Among the tires BKT touted were the Earthmax SR 41, the Earthmax SR 45 M and the Earthmax SR 53.

According to BKT, the Earthmax SR 41 is ideal for loaders and dozers in transport and loading and grading applications. The model stands out for its resistance to punctures and its durability, the company says.

The Earthmax SR 45 M serves as a solution for long-haul operations. The Earthmax SR 53 is designed for loaders, dozers and low-profile dump trucks operating under harsh conditions in rock environments – including operations in underground mines and at demolition sites.

Related: Crushing solutions that emerged at AGG1