Tough, quiet hydraulic breakers built for quarry work

Blue Diamond Attachments introduced a line of hydraulic breakers designed for construction, demolition and quarry applications. The line includes 12 models that are compatible with excavators, mini-skid, skid steers and compact track loaders. Blue Diamond says its offerings fit equipment ranging from 1,500 lbs. to 55-ton class excavators. The company’s breakers feature a solid, mono-block design milled from a single piece of steel, rather than assembled sections held together with tie rods that stretch. This helps eliminate common breaker maintenance issues, the company says.

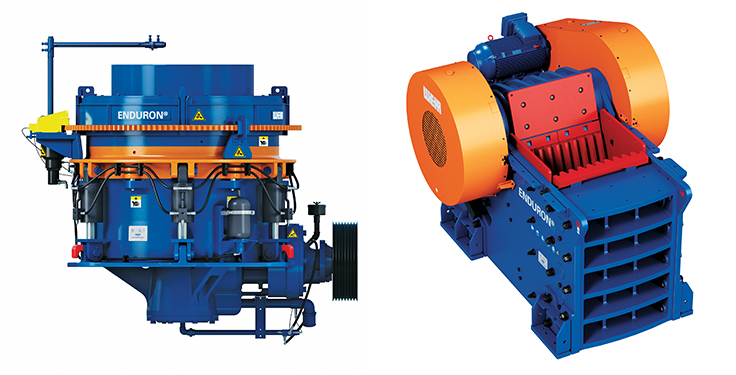

Redesigned crushers enhance safety, efficiency

Weir debuted its new range of Enduron jaw and cone crushers. The updated Enduron jaw crushers (pictured at upper left) feature a redesigned hydraulic power unit that allows for push-button control of closed-side setting adjustments. According to Weir, the innovation eliminates the need for manual intervention, reducing safety risks for operators and maintenance teams. The upgraded Enduron cone crushers, meanwhile, benefit from Esco wear liners and a newly designed hydraulic and lubrication power unit. Weir says the compact, plug-and-play system reduces environmental footprint and simplifies installation, making it ideal for sites aiming to streamline setup and minimize impact.

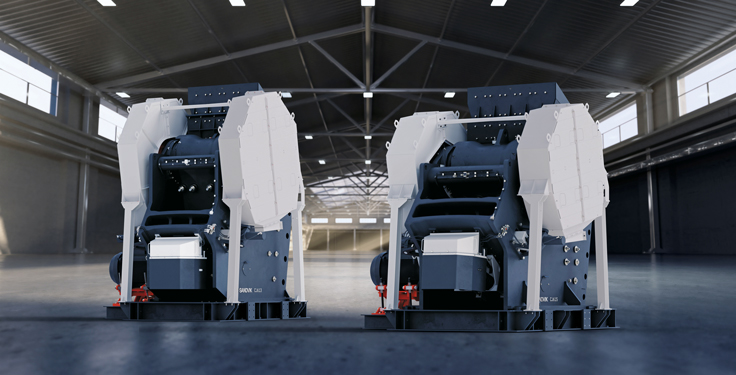

Next-gen jaws simplify monitoring, maintenance

Sandvik debuted a range of jaw crushers that offers new benefits in safety and performance. The upgrades include a new hydraulic wedge setting adjustment, a synchronized retraction arrangement, an improved power pack, upgraded guarding and clear, role-based user documentation. Additionally, Sandvik says its upgraded jaw crushers are manufactured with a welded mainframe and feature material quality improvements. The jaw crushers are equipped with Sandvik’s new ACS-j system, simplifying monitoring and control of lubrication, hydraulic settings and eccentric shaft bearing temperature.

Related: Hydraulic breaking equipment for producers to consider