Masaba introduced a new line of self-contained hydraulic radial stacking conveyors. The road- and pit-portable units operate under their own power via a 72-hp Yanmar onboard diesel hydraulic power unit that makes them suitable for remote operations and jobsites. According to Masaba, the new stackers are built to the same specifications as its traditional electric-powered stackers, but they are not limited to lighter steel weights and brandless components. The self-contained stackers are currently available in a standard belt width of 36-in. and in standard lengths of 80 and 100 ft. The company intends to offer additional lengths in the future, and it will work with customers who desire custom widths and lengths.

Redesigned electromagnets optimize performance efficiency

A new suspended electromagnet series from Eriez features units with stronger magnets housed in smaller enclosures, reducing overall weight and installation costs while optimizing performance efficiency. The new SEV series is integrated in the Eriez SE7000 line, with the new models leveraging wire and conductor technology to energize the magnet circuit. The company says the new electromagnets require less coolant for operation, and the new wire configuration, which features an ultra-thin anodized insulation layer, provides superior thermal conductivity and ensures high-heat dissipation within the circuit for improved magnet performance.

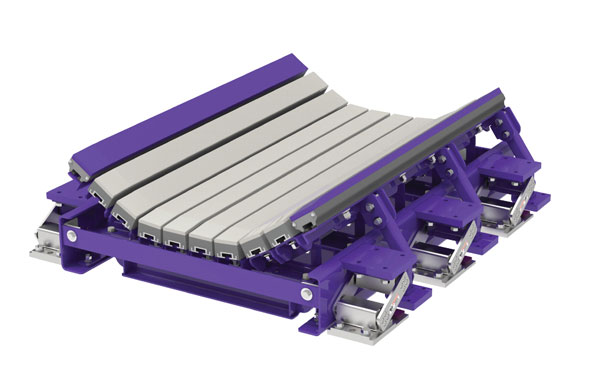

Impact bed ideal for load zone management

Flexco added the DRX 4500 to its line of impact beds and skirting systems. By utilizing velocity reduction technology, the company says this new rendition gives heavy-duty belt conveyor systems the ability to withstand impact energy from 1500 to 4500 lb. ft. Additionally, Flexco says the DRX 4500 provides protection for a heavy-duty facility’s entire structure – all while working for a litany of different belt conditions. Sites can expect to use the DRX 4500 for belt speeds up to 1,000 fpm, operate within temperatures ranging from minus 40 to 180 degrees, and work with belt widths measuring 36 to 96 in. The DRX 4500 is available in 5-ft. bed lengths, as well as in troughing angles from 20 and 35 degrees.

Secondary belt cleaner model surfaces

Martin Engineering’s SQC2S Orion secondary conveyor belt cleaner features individually cushioned tungsten carbide blade cartridges for effective cleaning without risking the belt or splices. A two-tiered tensioning system means minimal adjustments and monitoring throughout the life of the blade. The company says blades are mounted on a slide-in, slide-out assembly for faster and safer one-worker external servicing.

Related: Prioritizing safety, training and parts replacement