The new 444 G-Tier wheel loader caters to a segment of the construction market that values simplicity and reliability, according to John Deere. The company says the loader also serves as a response to a demand for more economically priced loader options that do not compromise on quality and durability. According to John Deere, the 444 G-Tier offers similar productivity as other models in its size class. The 444 G-Tier can be equipped with high lift to expand the reach of the machine, as well as a debris package that features a centrifugal air pre-cleaner and an auto reversing fan, helping to reduce downtime by enabling operators to stay up and running on a job without pausing to remove jobsite debris.

Build & maintain haul roads for large truck fleets

The GD955-7 motor grader, which is new to the North American market from Komatsu, offers operators the control and precision needed to build and maintain haul roads for truck fleets of 100 tons and up. The machine offers 426 hp at 1,900 rpm, as well as a powerful blade downforce pressure for efficient grading performance. With faster working travel speeds compared to a previous model, Komatsu says the GD955-7 is engineered to increase grading efficiency while reducing maintenance requirements and total cost of ownership. The motor grader can execute tight U-turns on a standard 100-ton-class haul road without the need to fully cut the wheel or course correct, and the long wheelbase and 27-degree articulation angle allow for a tight turning radius while providing maneuverability for narrow haul road applications in confined spaces and around obstacles.

Belt tracking device addresses production efficiency

The Tracker HD belt tracking device from Martin Engineering features upper and lower units that provide immediate, continuous and precise adjustment of mistracking belts. The results are greater productivity with less unscheduled downtime related to equipment replacement and spillage cleanup, the company says. As Martin Engineering describes, the Tracker HD’s precision comes from sensing rollers that ride either side of the belt edge and are attached to the end of an arm assembly. As the rollers detect slight variations in the belt path, the force of the wandering belt causes the arms to automatically position a pivoting idler in the opposite direction of the misalignment. The lever action requires less force to initiate the correction, the company adds, and only slight adjustments mean the consistent contact between the belt and idlers reduces the energy needed to bring the belt back into alignment.

Meet production demands, simplify inventory management

Command Alkon unveiled a new offering that’s designed to automate the movement of raw materials to plants and construction sites. According to the company, its new Material Supply is a Command Cloud-driven solution that’s designed to help material producers meet their production demands while removing the complexities of inventory management, ordering, billing and hauler management. Command Cloud is latest evolution of Command Alkon’s Connex platform, harnessing advancements in machine learning, generative AI, predictive analytics and IoT-enabled technologies.

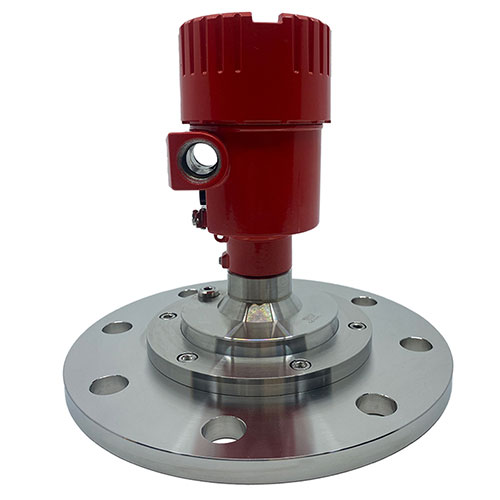

Measure solids across vessels & sites

The NCR-86 radar level sensor is designed to streamline bulk material inventory management. When paired with BinCloud software, BinMaster says the NCR-86 becomes a singular solution for measuring any solid or liquid commodity across vessels and sites – all accessible through a single login. According to BinMaster, the NCR-86 adapts to any level measurement application by providing 1-mm accuracy for solids, powders or liquids of varying bulk density or specific gravity. Despite challenging conditions like dust, foam, steam or condensation, BinMaster says the NCR-86 ensures rapid data updates and enhances efficiency in inventory management.

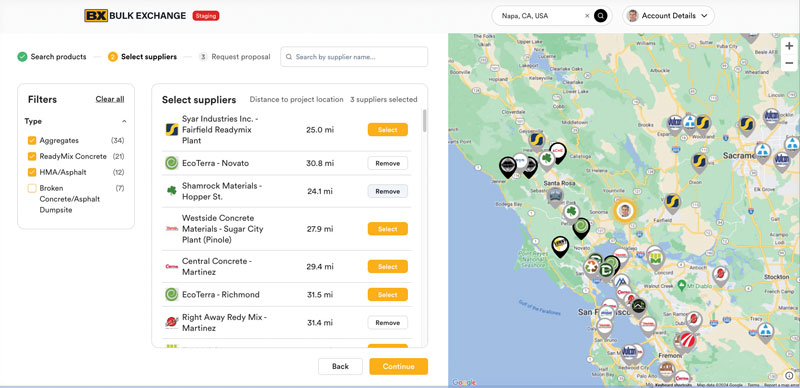

Online platform allows for buying, selling materials

Bulk Exchange launched as a bulk materials marketplace for suppliers, dumpsites, contractors and estimators. As Bulk Exchange describes, the supply and demand sides in bulk materials can now connect via a central marketplace, making it easier to buy, sell and move materials. The Bulk Exchange marketplace provides an industry-specific search engine with comprehensive solutions for finding and listing materials, accessing list prices and submitting or responding to RFPs, according to Bulk Exchange.

Train a belt as conditions change

A new return training bracket from PPI (Precision Pulley & Idler) provides users with a solution to knock idlers and reduce labor. According to PPI, the design allows the drop bracket to remain bolted to the conveyor framework while allowing for easy roll adjustments. As PPI describes, conveyor belt tracking has always been a material handling challenge. And often, such devices have proven to be ineffective or cost prohibitive. One of the most effective methods for training a belt, however, is knocking or skewing idlers. The process is often overlooked, PPI adds, due to the amount of labor – as well as the safety concerns – involved in adjusting brackets to fine-tune the belt path. By strategically positioning return training brackets in a conveying system, PPI says users now have the ability to easily train a belt as conditions change within the application.