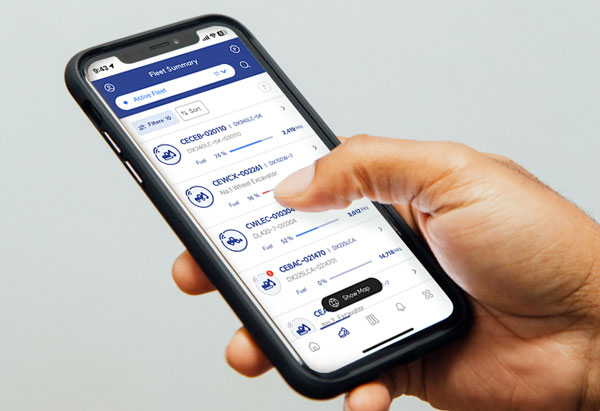

My Develon is the latest iteration of Develon’s fleet management system. Dealers and end users can access and manage Develon construction equipment maintenance and operation data using the My Develon app or a web browser. Customers can remotely check the status of their equipment and communicate with their machines by sending messages. Some of the features now available on the My Develon platform include the ability to download service tools and get personalized quotes on parts for Develon equipment.

Optimized comfort means more productivity

Hitachi Construction Machinery Americas filled out its Zaxis-7 line of medium and large excavators earlier this year with the ZX250LC-7, ZX300LC-7, ZX350LC-7, ZX490LC-7, ZX690LC-7 and ZX890LC-7. Ranging in operating weight from 58,433 to 192,938 pounds, the excavators include upgraded features that enhance operator comfort, visibility, fuel efficiency, durability and productivity. Hitachi says comfort was a priority when redesigning the operator station. The Zaxis-7 cab, for example, is larger with less vibration and noise for an improved operating experience and reduced operator fatigue. Additionally, noise was minimized by increasing the thickness of the rear glass. Also, a seal was added between the cab and floor plate, improving the airtightness of the cab to keep dust out.

Midsize loader addresses reliability, affordability

The 444 G-Tier wheel loader caters to a segment of the construction market that values simplicity and reliability, according to John Deere. The company says the loader is a response to demand for more economically priced loader options that do not compromise on quality and durability. According to John Deere, the 444 G-Tier offers similar productivity as other models in its size class. The 444 G-Tier can be equipped with high lift to expand the reach of the machine, as well as a debris package that features a centrifugal air pre-cleaner and an auto reversing fan, helping to reduce downtime by enabling operators to stay up and running on a job without pausing to remove jobsite debris.

Midsize wheel loaders get engine upgrades

The L110H and L120H midsize wheel loaders were upgraded with a new Volvo D8M eight-liter engine that offers 256 hp on the L110H and 272 hp on the L120H. According to Volvo Construction Equipment, the D8M engine automatically regenerates while working and features a new electric pump for priming the fuel system, making the process quicker and more convenient than with the former manual pump. When fuel gets to the engine, users can be confident it is clean thanks to new captive fuel filters, Volvo CE says. These not only ensure good water separation, but they help to extend engine service intervals to 1,000 hours.

Loader an option for high-volume applications

The HL985A wheel loader from Hyundai Construction Equipment Americas features a standard bucket capacity of 9.1 cu. yd. Considered a “true two-pass” wheel loader because it can fill an HA30 articulated dump truck with two bucket loads, Hyundai says the HL985A combines power, performance, fuel efficiency, operator safety and comfort. A 430-hp Cummins X12 Performance Series engine powers the wheel loader, meeting Tier 4 Final emissions standards. The HL985A is available with Hyundai’s All-Around View Monitoring system that includes four cameras that provide 360-degree views and incorporates motion detection for enhanced operator and jobsite safety.

New option coming on crawler excavator

The R 924 G8 crawler excavator is a powerful and versatile machine combining high productivity, flexible operation and precision, according to Liebherr. The R 924 G8 is now equipped with Skyview 360°, an option that will be available to order this fall. The system allows operators to monitor the working area around the machine on a single screen, providing a bird’s eye view with no blind spots. At a single glance, the operator can see through 360 degrees and rapidly identify danger areas to improve safety and productivity.

Battery electric model an alternate solution

The 856H-E MAX wheel loader from LiuGong draws upon the company’s range of electric construction vehicles worldwide. A 432-kilowatt hour large-capacity lithium-ion phosphate battery from CATL powers the 856H-E MAX. LiuGong says the machine is capable of 10 hours of working time for light applications and eight hours for heavy applications. The loader features an intelligent battery management system that can be fast charged in 90 minutes.

Related: Seven tips for mastering summer excavator maintenance