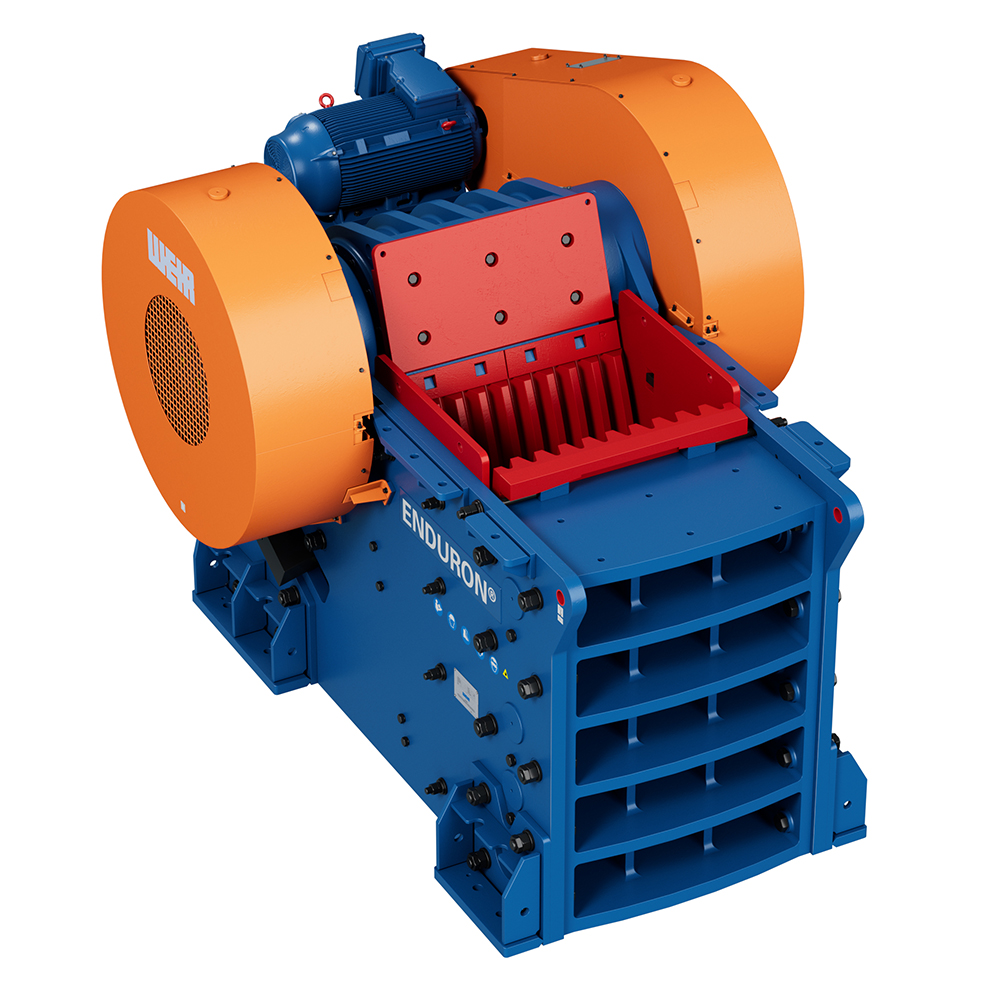

Weir debuted its new range of Enduron jaw and cone crushers.

“We’ve listened closely to our customers and designed this range to meet their evolving needs,” says Magnus Skorvald, global product manager of crushers at Weir. “From safety and sustainability to ease of installation and maintenance, every feature is built to deliver real value on-site.”

The updated Enduron jaw crushers feature a redesigned hydraulic power unit (HPU) that allows for push-button control of closed-side setting adjustments. According to Weir, the innovation eliminates the need for manual intervention, reducing safety risks for operators and maintenance teams.

The new HPU ensures consistent tensioning of the retraction springs at all times, Weir adds. This improves reliability and ease of use across the full wear range of jaw dies. Weir says optimized motor power and oil tank capacity reduce the HPU’s carbon dioxide footprint and environmental impact.

Additionally, the entire range of Enduron jaw crushers now includes Esco wear parts.

The upgraded Enduron cone crushers, meanwhile, benefit from Esco wear liners and a newly designed hydraulic and lubrication power unit. Weir says the compact, plug-and-play system reduces environmental footprint and simplifies installation, making it ideal for sites aiming to streamline setup and minimize impact.

Additionally, the automation platform across all cone crusher models was enhanced to ensure consistent and reliable crushing operations. With IO-link digital sensors and Siemens PLC hardware, Weir says customers can expect seamless integration, easier troubleshooting and intuitive control through a new human-machine interface that simplifies servicing and improves operational efficiency.

Weir’s new crusher range includes the Enduron ET jaw crushers and the EP fixed-shaft and EC live-shaft cone crushers.

Related: How telematics systems are reshaping crushing operations