The Falcon sand plant from EIW (Eagle Iron Works) offers a high product yield in a compact washing system that produces a drip-free, stackable, easy-to-handle product. The Falcon is a sump-fed system that’s comprised of a sump, hydrocyclone(s), a dewatering screen and a pump. EIW says the Falcon’s heavy-duty design and easy maintenance make it the ideal wash plant for operations seeking a high sand-recovery solution. The plant’s modular design makes setup quick and simple, so operations are up and running sooner. Additionally, the company says the plant’s compact design allows for maximum use of land resources.

Modular solution makes use of waste material

The UltraScrub, which is part of McLanahan Corp.’s offerings to recover usable material from concrete, rubble and other aggregate waste products, is a modular scrubbing option that can be configured to include the company’s range of log washers or coarse material screw washers. According to McLanahan, the UltraScrub represents a flexible scrubbing and sizing option to remove difficult materials and break down contaminants before flushing them out with wastewater. The UltraScrub ships in containerized modules to allow for easy transportation and quick setup, the company adds.

Build in custom features to stationary, portable plants

General Steel & Supply Co., a Fisher Industries company, custom designs and mounts wash plants with most major brands of washing equipment. The wash plants can feature single- and multiple-deck screens; single- and twin-paddle log washers; single- and twin-shaft sand screws; coarse material washers; sand pumps; water manifold and spray bars; and slurry feed boxes. Additionally, the company’s wash plants can be designed as either a stationary or portable plant. Some of the features that can be included are stationary structured frames; portable chassis frames on axles and tires; walkways, handrails and platforms for maintenance and service; ladders for easy access; and electrical switchgear.

Filter press designed for sludge dewatering

The ProPress filter press was added to CDE’s water management and recycling system offerings. Described by CDE as its “most significant product launch in recent years,” the ProPress was developed to meet the needs of the quarrying, mining and C&D waste recycling industries. According to the company, ProPress users benefit from a flexible design and variable throughput that can be scaled to fit the processing volume of any operation. Unlike traditional filter presses, the CDE system is dual feed, meaning sludge is fed from both sides of the ProPress for what the company describes as “improved efficiency and faster cycle times.” Additionally, CDE says optimized sludge feed pressure allows for faster dewatering to increase overall throughput. An overhead beam design supports this, reducing stress on the unit and improving its durability.

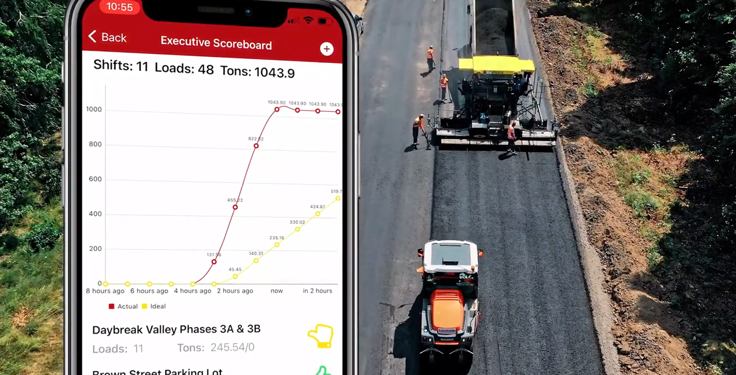

Software to enhance productivity and reduce downtime

The Stream software system from Terex Washing Systems harnesses real-time data to provide operators with insights, enhance productivity, reduce downtime and maximize profitability. As Terex Washing Systems describes, Stream revolutionizes the way operators interact with their equipment by delivering descriptive, predictive and actionable information. With the ability to track tasks and keep records via a mobile app, Stream simplifies maintenance management and allows users to unlock greater efficiency on the go. According to the company, Stream offers a comprehensive overview of connected assets, providing users with data such as production figures, machine status and maintenance notifications.

Related: 6 tips to prolong the life of your coarse material washer