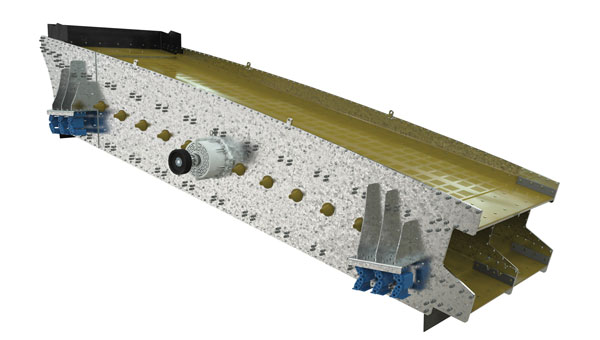

The P2-168 Infinity screen from CDE features a processing capacity of up to 700 tph, according to CDE. The P2-168 is the largest model in the Infinity range, and CDE says it is designed specifically for the U.S. market. According to the company, the construction of Infinity screens makes them fundamentally different from other screens available on the market. With no welds in the sidewalls, a galvanized structure and a VibroSync drive mechanism providing control and even distribution of power, CDE says the P2-168 offers increased durability and prolonged operational life for advanced screening and dewatering performance.

Produce up to three washed aggregates, two washed sands

The Aggresand 206 integrated sand washing plant is readily portable and particularly suitable for greenfield applications, contractor users and temporary planning permission sites, according to Terex Washing Systems. The company says operators who are used to static installations will appreciate the small footprint and minimal site preparation required for the plant. The range includes a number of modular configurations, but all are based around the choice of a 16-ft. x 5-ft. or 20-ft. x 6-ft. wash screen and a choice of sand output capacities.

Modular systems offer unique advantages

Superior Industries’ modular plant packages, known as Fusion platforms, include dozens of options for aggregate washing applications. Superior says its modular systems offer bulk producers faster, more economical solutions to develop and commission a new processing plant. The company’s wet processing plants include pre-engineered systems for scrubbing, classifying, dewatering and washing using a combination of Superior’s blade mills, coarse and fine screws, logwashers, dewatering screens, cyclones and wet screens. Each system is designed with plug-and-play, pre-wired electrical connections and is optimized for efficient shipping, according to Superior.

Produce a drip-free, in-spec sand product

The Falcon sand plant from EIW (Eagle Iron Works) is a sand-washing solution that produces a drip-free, in-spec sand that is conveyable, stackable and ready for immediate sale. The Falcon consists of a sump, pump, hydrocyclones and a dewatering screen on a modular chassis for easy and rapid setup. According to EIW, the Falcon has configurable left or right access walkways and a hydrocyclone underflow access platform, as well as a pump drain that allows for easily emptying the system during cold weather shutdowns. The Falcon has a heavy-duty design for long life and high throughput, the company adds, and it is compact enough to fit in a small footprint.