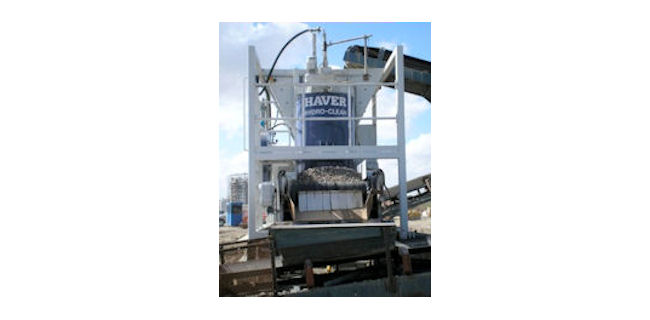

The Haver Hydro-Clean washing unit from W.S. Tyler cleans deleterious material from aggregate effectively while reducing water consumption by up to 75 percent and energy costs by up to 15 percent over traditional log washers, the company says. Taking a maximum feed material size of up to 6 in. into its vertical drum, the Hydro-Clean employs high-pressure nozzles, rotating at 90 rpm, to spray up to 90 percent recycled water on the material with pressures up to 2,900 psi. The washing unit removes silt and clay particles as small as 63 microns from mineral mixtures and, with its short retention times, can process up to 400 tph, depending on model size and application. Due to its compact size and weight, overall operating and structural costs are considerably lower than with traditional washing systems, the company says.

Photo: W.S. Tyler