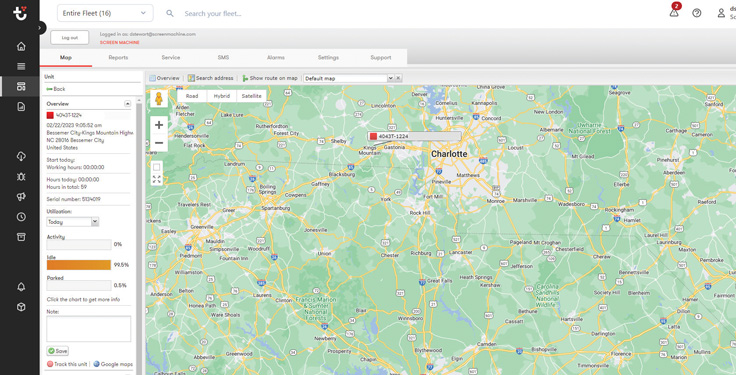

“It’s basically telematics ‘plus,’” says David Stewart, director of marketing at Screen Machine. “It provides real-time data on all your assets direct to the desktop or through the app. You can get updated service and warranty info at your fingertips. You can view all performance of your fleet, [and] there’s GPS tracking for all equipment locations. Very importantly, there’s alerts and alarms to keep you aware – and keep our product support team aware – of any critical issues with the machinery.”

Like Spective Connect, SmartWatch presents users of Screen Machine and Diamond Z equipment with an opportunity to troubleshoot equipment more effectively.

“The difference with SmartWatch is our product support team is tied into this very tightly,” Stewart says. “The moment an issue arises, they can tell you exactly where it is and what it is. So instead of sending out a tech to climb all over this massive machine to find out where the problem is, they can tell you a sensor’s out, a pump is out [or] you’ve got a DEF tank problem. That saves an estimated $1,500 every time you send a tech out to work on a machine. Over the course of a year, that’s a huge savings.”

Making digital a discipline

Although more digital technology is available to aggregate producers than ever before, the industry’s use of it is, in some ways, somewhat limited.

The industry’s use will likely escalate in the years to come, though.

“I think the industry will move more in that direction in the next couple of years,” says Russ Burns, sales director at Terex MPS. “It just makes sense for folks to be able to monitor equipment as telematics and other capabilities come around.”

Manufacturers, in many ways, are well in front of producers in terms of seeing digital as the future. They’re paving a path for customers that most will eventually follow.

“Digital is a huge focus for us as a company,” Albaugh says. “It’s also a huge focus for pretty much everybody I talked to, whether it’s our Aquavar IPCs [or] smart technology for our diesel-driven pumps. All of our products can be lit up so the owner/operator can see how they’re performing.”

Still, Baker says every end user’s foray into digital is different.

“It is a journey, and it kind of builds on itself,” he says. “Taking that first step is critical. You’ve got to walk before you run.”

Producers must have an appetite to improve with change, Baker adds, and they must be willing to stay disciplined at the first sign of adversity.

“You must be invested in taking the intelligence and acting on it,” he says. “Really, when customers start seeing the benefits, it’s like the flywheel effect: You build a few little success stories and see how a little change made you way better. You get a little bit of that, and it builds on itself. Then, the wheels start turning and customers are like: ‘Well, if we did that, what else could we do?’ Then, you start finding other things.”

Related: Running a modern quarry with digital technology