Track conveyor for most demanding quarry applications

The new TCL 2031 track-mounted conveyor is the latest addition to Telestack’s tracked conveyor line. The TCL 2031 extends the range with a design suited for applications ranging from 1,650 to 2,750 tph. It can handle a maximum lump feed size of up to 15.75 in. The conveyor can stack up to 5,070 cu. yd. of material in a single conical stockpile, and it can be easily moved to meet changing demands within a stocking area. The TCL 2031 features a 55-in. belt, mining-grade rollers, scrapers and bearings.

Disc coupling design increases torque capacity, eases rebuilds

Dodge Industrial launched the StratoLink disc coupling line as an expansion of its coupling portfolio. The first model to launch is the D71 Series, which meets API 610 standards and is engineered for maximum torque, simplified rebuilds and interchangeability in existing installations. The company says the D71 Series offers an average of 26 percent greater torque capacity on average and an average of 11 percent larger bore ranges. The model features a bushing engagement system that eliminates hammering and other unsafe rebuilding practices.

Modular pump targets high-wear slurry applications

KSB GIW debuted the GIW VMD as a new vertical slurry pump designed for abrasive and demanding slurry applications. According to the company, the GIW VMD sets a new standard for vertical pump technology by combining heavy-duty reliability with a fully modular construction. Its wet end, mechanical end and cantilever components are all interchangeable, enabling quick adaptation to different operating requirements. The flexible configuration facilitates rapid maintenance, simplified part replacements and easy customization to match specific site needs.

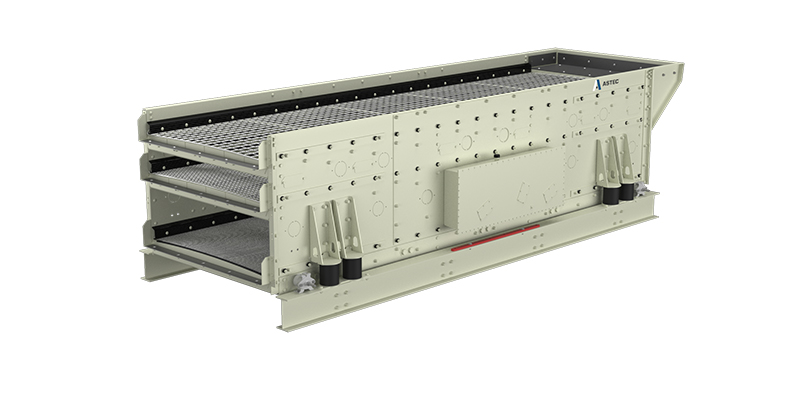

Updated scalping screen enhances performance, mobility

Screencore introduced the Trident 165 as the latest version of its flatbed scalping screen. According to the company, the new Trident 165 features design updates that enhance performance – including improved transportability, quick setup and intuitive control systems. The unit is a double-deck scalper with a 16-ft. x 5-ft. top and bottom screen. The full-size top and bottom decks ensure there is no loss of production due to a smaller bottom deck. Powered by a Cat C4.4 or C3.6 engine, Screencore says the Trident 165 was engineered for heavy-duty applications. It’s available with an apron feeder for extra heavy-duty operation.