Martin Engineering launched a factory-direct replacement program to deliver freshly molded polyurethane cleaner blades for conveyor belts. According to Martin, its blades are custom fitted on-site and installed free of charge, with customers only paying for replacement blades. The program assures customers of accurately sized and professionally installed replacement blades that are matched to their specific application, Martin says, with the company aiming to provide optimum cleaning performance and service life to minimize the cost of ownership. The program’s replacement blades are made with specially formulated, color-coded urethane to suit virtually any application.

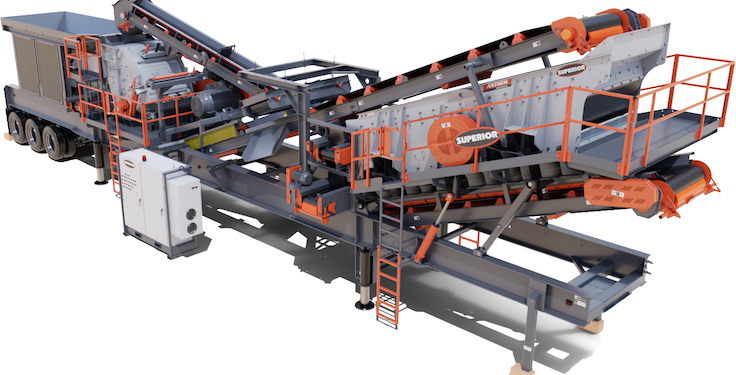

Portable HSI can process various materials

Superior Industries introduced a new portable horizontal shaft impact (HSI) plant that’s designed to process recycled concrete, reclaimed asphalt and pit-run materials. The new Sentry HSI is a closed-circuit model capable of producing up to four products, Superior says. The closed-circuit crushing and screening arrangement includes a 4250 Sentry HSI. A vibrating grizzly feeder, which is equipped with interchangeable grizzly cassettes, feeds the plant and accommodates use in multiple applications. Additionally, a two-deck Anthem inclined screen screens up to three material sizes. Superior says returning material is fed back to the HSI via a recirculating conveyor that centralizes the feed for full utilization and extended wear life of blow bars.

Cone plant aims for increased throughput, enhanced product shape

Terex MPS debuted the CRC1350 portable cone plant featuring the new TC1300X cone crusher. According to Terex MPS, the Cedarapids-branded plant is engineered to meet the growing industry trend toward larger, mobile, electric-powered, low-maintenance plants that provide an increased production capacity. The TC1300X cone crusher features 400 hp – a significant increase in power over a previous version, the company says. The TC1300X uses high-efficiency roller bearings and features advancements that enhance performance and functionality overall.

Telematics monitoring service offers new possibilities

Doosan Infracore North America launched a subscription-based telematics monitoring service that’s supported by a new machine-monitoring center in Suwanee, Georgia. The monitoring system is called Smart X-Care. Using a machine’s DoosanConnect telematics data, Doosan says its employees monitor subscriber machines via the monitoring center. When a machine alert is triggered, the telematics system sends two messages via email – one to the equipment owner and one to the dealer.