Dodge Industrial debuted the Optify breather as an intelligent desiccant breather allowing customers to tap into its condition monitoring platform. According to Dodge, Optify users can now remotely monitor breather status to extend gearbox life and streamline maintenance. The breather features sensor technology, providing precise data measurements and key performance indicators such as breather life, rate of saturation, internal gearbox headspace temperature, battery life and saturation direction. Dodge says the breather is compatible with the Optify platform out of the box, allowing users to quickly review asset status, compare like-asset data and analyze historical trends.

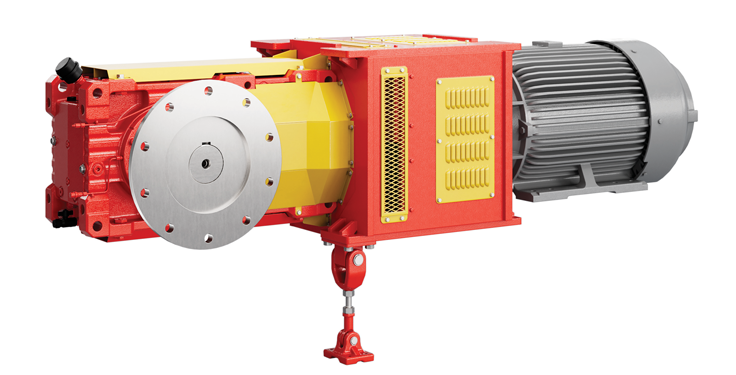

Industrial gear units meet requirements for aggregates

XMiner industrial gear units are designed for the demands of aggregate applications – including conveyor systems, crushers and apron feeders. Built on the X.e series platform, SEW-Eurodrive says the XMiner units are available with local engineering, stocking and assembly in Wellford, South Carolina. As SEW-Eurodrive describes, the units provide several benefits to operators, including reduced weight and cost thanks to a high power density, a cooling system that eliminates the need for cooling alternatives, reduced inventory and spares, and local engineering and application support for proper sizing.

Monitor machine health through web platform

The next-generation Perceptiv intelligent reliability and maintenance solution for condition monitoring and predictive maintenance offers customers a unified platform to meet growing reliability needs, according to Regal Rexnord. Perceptiv intelligence uses in-field sensors and gateways to monitor machine health. Collected data can be sent to a customer’s on-premises system through industrial protocols or to the Perceptiv web platform for online viewing. Through the platform, Regal Rexnord reliability engineers can analyze the data to provide customers with recommendations on how to extend equipment life and reduce unplanned downtime.

Conveyor belt drives eliminate maintenance concerns

VDG’s GrizzlyDrive drum motors are designed and manufactured to endure the demands of belt conveyors operating in mining and aggregate applications. All drive components, including the electric motor, gear reducer and bearings, are enclosed inside the drive drum and protected from harsh, dusty and abrasive environments. The drive components are designed for 80,000 hours of continuous operation before maintenance, VDG says, reducing operational and maintenance costs. Additionally, the company says the new premium-efficiency electric motor operates at low temperatures, increasing the reliability and service life of the GrizzlyDrive.

Related: Regal Rexnord showcases products, company performance at media event