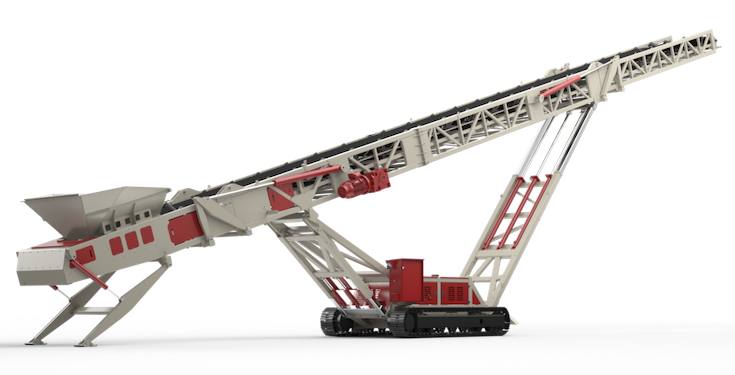

Telestack launched the TCL 2031 track-mounted conveyor as the latest addition to its tracked conveyor line.

The TCL 2031 follows the TCL 1031 track-mounted stacker, which handles applications up to 1,100 tph and 0 to 10-in. primary jaw crusher operations. The TCL 2031 is suitable for applications ranging from 1,650 tph to 2,750 tph and can handle maximum lump feed sizes of up to 15.75 in. Telestack says the conveyor can stack up to 5,070 cu. yd. of material in a single conical stockpile and can be easily moved from position to position to meet the demands within the stocking area.

The TCL 2031 sports a 55-in. belt, mining-grade rollers, scrapers and bearings. According to the company, the conveyor is designed to fill the gap for large quarries, mining and aggregate operations using high-capacity crushers.

Hydraulic folding head and tail sections collapse the machine for road transport to a folded length of 58 ft. and a transport height of 14 ft. 5 in. Alternatively, it can be broken down into shipping containers for long-haul moves. According to Telestack, on-site setup takes less than 30 minutes.

For site mobility via the track system, the unit uses an integrated diesel hydraulic engine with regional engine options including a 100kw, 130 hp Cat engine or an 86 kw, 100 hp Deutz engine (both Stage V), as well as a Stage III Cat 96.4 kw engine.

Once the unit is in position, it is driven by all-electric drive motors via an electric wrap drive, in which three-phase power is plugged into the control panel of the TCL 2031 during operation, ensuring maximum efficiency using on-site electrical power or auxiliary power from the existing jaw crusher. There are also options for a fully electric system for certain sites where diesel hydraulic engines are not permitted, according to Telestack.