Kobelco Construction Machinery USA introduced a 55-ton excavator for mining and construction applications. The new SK520LC-11, which is part of Kobelco’s -11 series, has an operating weight of about 121,000 pounds, offering what the company describes as top-performing cycle times, lift capacity and digging force. The excavator delivers a bucket digging force of 72,200 pounds and features a lifting capacity of 46,540 pounds. A 463-hp Tier 4 Final Isuzu 6WG1 engine powers the excavator. Independent travel, a Kobelco feature, enables the SK520 to move, lift and swing simultaneously without experiencing loss of power.

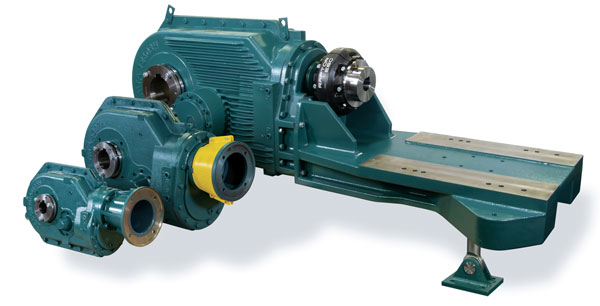

Motorized torque-arm enhancements elevate gear reducer performance

Dodge Industrial unveiled advancements in its motorized torque-arm (MTA) lineup. According to Dodge, its MTAs are the only AGMA-rated direct-drive reducers. Now, the company’s MTA lineup is larger and offers new capabilities. Larger 9, 10 and 12 reducers, for example, now support up to 329,000 inch-pounds of torque. Additionally, assembly packages with reducers sized 7 to 12 and Atlas Adapter support large foot-mount motors 60 hp and above, reducing the need for spare motor inventory by allowing the use of standard foot-mount motors in sizes not commonly stocked in C-face styles. Dodge says C-face safety input adapters enable access to the coupling through a split cover to eliminate the need to remove the motor.

New medium, large excavators surface with upgrades

Volvo CE launched a new range of excavators with upgrades that include greater fuel efficiency, increased productivity, enhanced safety and other operator-friendly features. As the company describes, its new series represents the most significant update to the Volvo excavator lineup in 20 years. The initial launch includes multiple medium and large excavator models in North America – including the ECR145 short swing, the EC210, the EC230, the EC370, the EC400 and the EC500 crawler excavators. More models will launch in the coming months.

Solution to monitor machine health

Regal Rexnord Corp. debuted the next-generation Perceptiv intelligent reliability and maintenance solution for condition monitoring and predictive maintenance in industrial manufacturing. This next evolution of the Perceptiv ecosystem offers customers a unified platform to meet growing reliability needs, the company says. Perceptiv intelligence uses in-field sensors and gateways to monitor machine health. The collected data can be sent to a customer’s on-premises system through industrial protocols or to the Perceptiv web platform for online viewing. Through the web platform, Regal Rexnord reliability engineers can analyze the data to provide customers with recommendations on how to extend equipment life and reduce unplanned downtime.

Related: MINExpo preview: What Brokk has in store for showgoers