vibrating screens

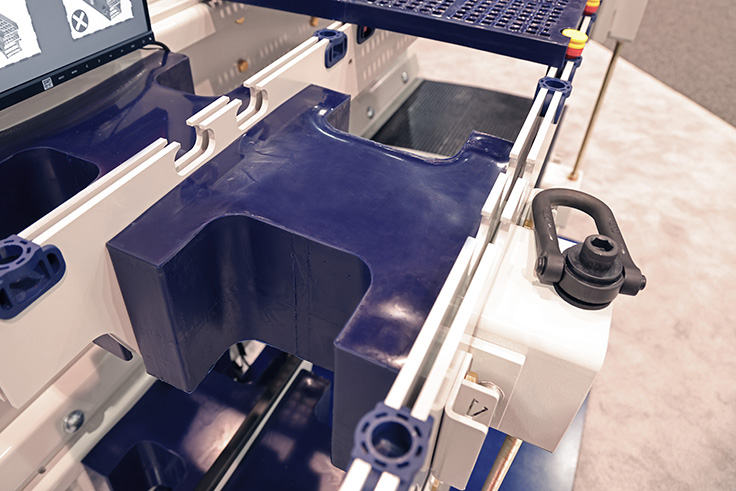

New wear liners provide cross beam protection

Haver & Boecker Niagara’s Drop Guard wear liners replace the company’s Zip Guard and Snap Guard options on next-generation Niagara vibrating screens. Keep Reading

7 steps to work into vibrating screen walk-arounds

There are several measures and best practices operators should take to optimize the performance of their vibrating screens. Keep Reading

Haver & Boecker Niagara showcases new wares at MINExpo

The new F-Class vibrating screen features new technology, is built with lockbolts rather than welding and maximizes open area. Keep Reading

Haver & Boecker Niagara to highlight Pulse software at MINExpo

The company's vibration analysis software offers aggregate operations insights about equipment performance. Keep Reading

Why partnering with an OEM can optimize vibrating screen health

By partnering with a technical vibrating screen OEM, operations can rely on a team that manufactured the equipment, offering comprehensive diagnostic tools and more. Keep Reading

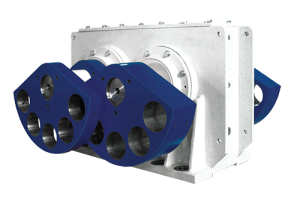

Haver & Boecker Niagara exciters offer improved screening performance

Niagara Exciters are engineered by Haver & Boecker Niagara to set the required stroke, frequency and exact static moment for each application. Keep Reading

Make the old new again, save money with refurbishments

With just four simple steps, manufacturers can update old screening equipment at nearly half the cost of purchasing a new machine. Keep Reading

Haver & Boecker Niagara XL-Class Vibrating Screen

The Niagara XL-Class vibrating screen combines advanced exciter drive technology with a wide body to offer high-capacity screening action at up to 15,000 tph. Keep Reading

Haver & Boecker Niagara launches vibrating screen analysis service

The service will help customers minimize unscheduled downtime while achieving production targets, according to the company. Keep Reading