vibrating screens

The latest equipment considerations for aggregate operations

Check out the latest in cutting-edge equipment from Hyundai Construction Equipment Americas, Haver & Boecker Niagara, Martin Engineering and Caterpillar. Keep Reading

How to successfully set up vibrating screens

Presenting ways aggregate producers can determine the proper screen size, the right number of decks and which media to use. Keep Reading

The true cost of fabricated parts

While a fabricated component may seem to make sense at first due to lower cost, any minor imperfections could result in damage and downtime. Keep Reading

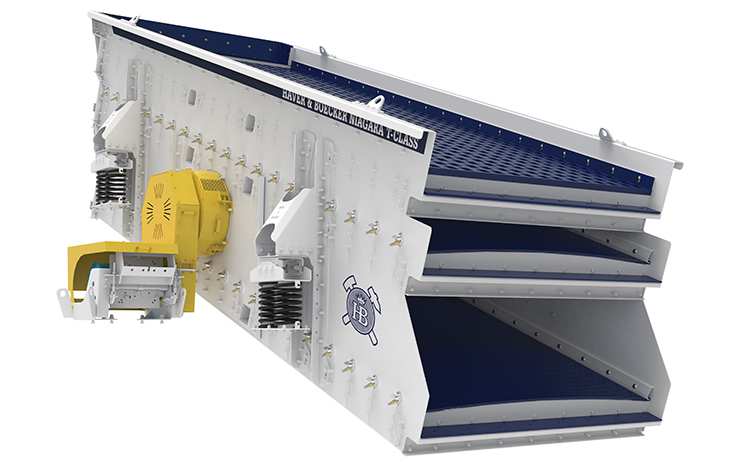

Next-generation screen enhances uptime, performance

Haver & Boecker Niagara’s T-Class vibrating screen is capable of processing a variety of materials. Keep Reading

Equipment to boost screening operations

Some of the latest screening equipment and tech comes from Rhino Hyde, Unified Screening & Crushing, Conn-Weld Industries and Hoyt Wire Cloth. Keep Reading

How to find the right screen media formula

Steve Fair, Tyler engineered media manager at Haver & Boecker Niagara, outlines how to find the right screen media formula and the importance of doing so. Keep Reading

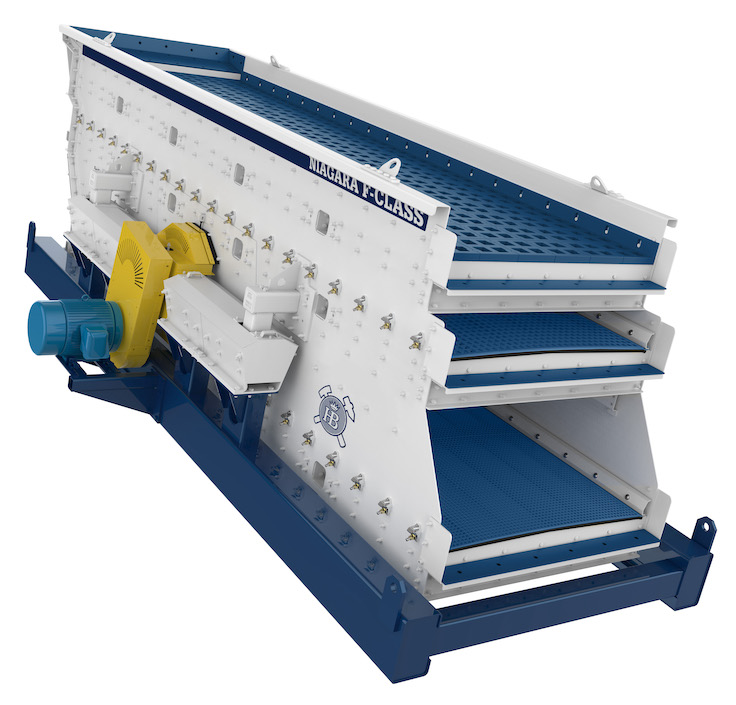

Haver & Boecker Niagara to highlight new F-Class screen

Haver & Boecker Niagara plans to showcase its updated signature Niagara F-Class vibrating screen at AGG1 this year. Keep Reading

How vibration analysis boosts producers’ bottom lines

Diagnostic tools like vibration analysis have the ability to improve and maintain vibrating screen performance and reduce maintenance costs and downtime. Keep Reading

How vibration analysis makes life easier for screens

Lars Bräunling of Major explains how aggregate producers can use vibration analysis tech to prevent unforeseen breakdowns, as well as optimize performance. Keep Reading