maintenance

Selecting the right screen media

Determining the ideal choice is very much dependent on the application at hand. Learn more about the factors that should play into your decision. Keep Reading

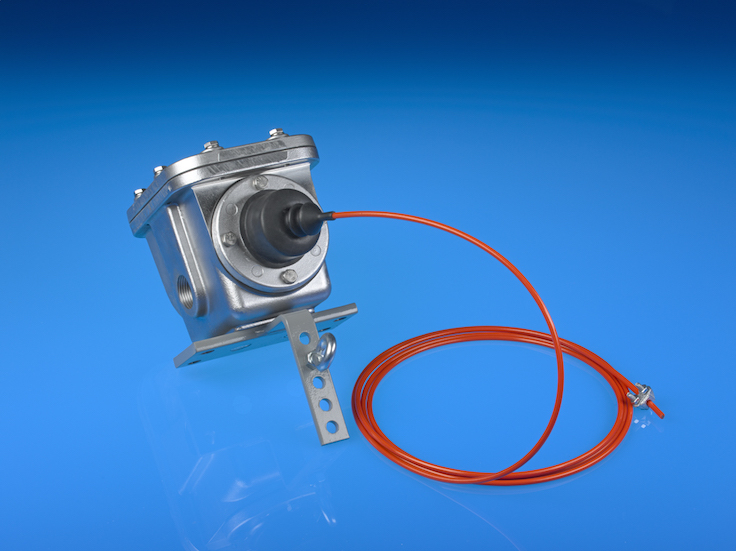

Belt rip detector aims to save downtime

Conveyor Components Co. introduced the Model DB belt rip detector, which can minimize conveyor belt damage and keep belts clean and functional. Keep Reading

Strategies to maximize trailer longevity, safety

To get the most out of trailers, there are some key steps to take that prevent costly damage and keep trailers in tiptop shape. Keep Reading

Shell Gadus S3 grease now dually certified

Shell Gadus S3 V220C 2 grease is now both NLGI GC–LB and NLGI HPM +HL certified, according to the company. Keep Reading

NTN releases ceramic ball bearings for electric motor applications

NTN’s new ceramic ball bearing offering comes with two shields, electric motor grease and C3 clearance as standard. Keep Reading

Motion names vice president of operations integration

John Watwood, who joined Motion in 2008, is now responsible for the company’s distribution and fulfillment network, branch operations support and enterprise excellence. Keep Reading

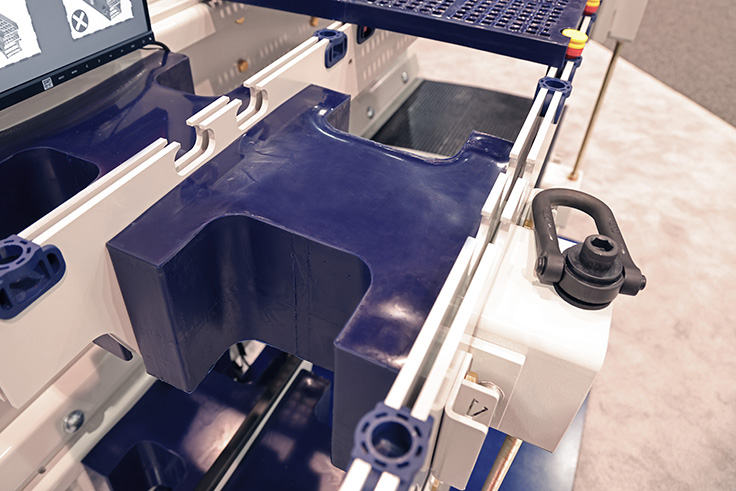

New wear liners provide cross beam protection

Haver & Boecker Niagara’s Drop Guard wear liners replace the company’s Zip Guard and Snap Guard options on next-generation Niagara vibrating screens. Keep Reading

Changing the conversation on maintenance costs

Josh Swank with Philippi-Hagenbuch offers considerations mine managers should make to set their operation for years of success. Keep Reading

7 steps to work into vibrating screen walk-arounds

There are several measures and best practices operators should take to optimize the performance of their vibrating screens. Keep Reading