Luff Industries

Luff Industries: Belt Brush Cleaners

Photo: Luff Industries Luff’s Belt Brush Cleaning Unit is available in a variety of sizes to accommodate any belt cleaning application needed. Driven by its own electric motor, the brush turns opposite to the direction of the belt travel, delivering… Keep Reading

Luff Industries: Quality Conveyor Components

Photo: Luff Industries Celebrating its 45th Anniversary in 2024, Luff continues to supply high-quality, long-lasting conveyor components all over the world. Luff products are manufactured to withstand the harshest applications and can be used with confidence in medium to heavy… Keep Reading

Gallery: Sights from the AGG1 show floor

Check out a gallery of photos showcasing some of the people the magazine encountered across the three-day AGG1 last week in Nashville. Keep Reading

Quarry Faces: March 2024

Check out photos from P&Q’s travels — including a visit to the Ontario Stone, Sand & Gravel Association’s Operations, Health & Safety Seminar and the Pit & Quarry Roundtable & Conference. Keep Reading

Conveying solutions to improve efficiency

A range of conveying equipment unveiled at ConExpo-Con/Agg offers producers new opportunities to modernize their systems. Keep Reading

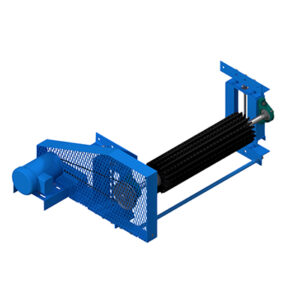

Luff Industries impact beds

Luff’s frame design allows for the impact bars to be easily replaced without removing the skirting, reducing downtime and maintenance costs. Keep Reading

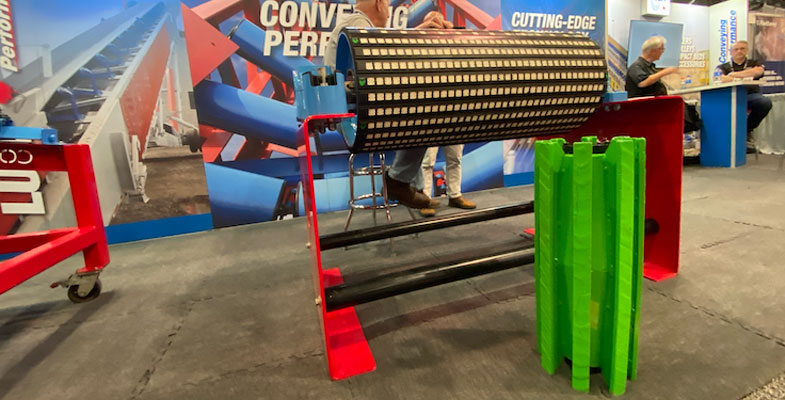

Luff Industries Wear Wolf Wing Pulley

The proprietary material blend, that boasts 66 Rockwell C while maintaining ductile properties, is used when manufacturing the new Wear Wolf Wing Pulley. Keep Reading

Keeping qualified employees in a candidate-driven market

The aggregate industry continues to face a shortage of qualified workers as older generations retire. Industry experts discuss how employers can find and retain qualified employees in a tough market. Keep Reading

Luff showcases wing pulley at ConExpo

Luff Industries highlighted its Wear Wolf wing pulley alongside other equipment at ConExpo-Con/Agg. Keep Reading