Haver & Boecker Niagara

Possible stocking solutions for supply shortages

The demand for equipment and wear parts amid supply shortages opens the door for special programs allowing customers to better manage operational needs. Keep Reading

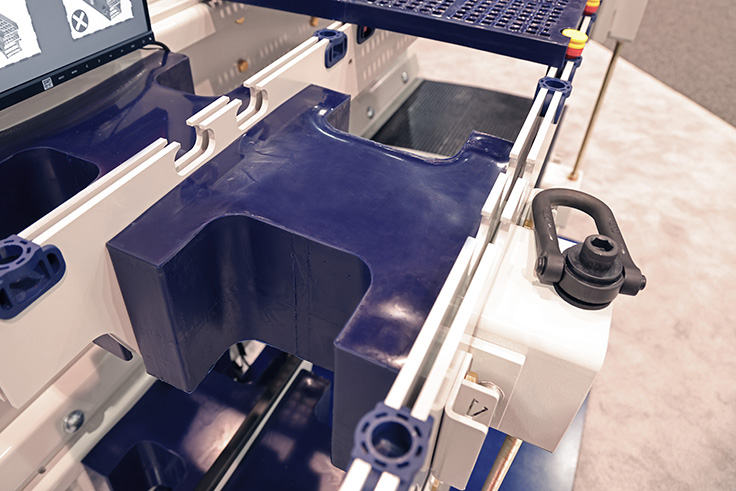

New wear liners provide cross beam protection

Haver & Boecker Niagara’s Drop Guard wear liners replace the company’s Zip Guard and Snap Guard options on next-generation Niagara vibrating screens. Keep Reading

7 steps to work into vibrating screen walk-arounds

There are several measures and best practices operators should take to optimize the performance of their vibrating screens. Keep Reading

Equipment, technology developments you may have missed

Caterpillar, Hitachi and Weir Minerals are among the equipment manufacturers with new equipment and technology that aggregate producers can explore. Keep Reading

Supply chain issues causing waiting game for producers, dealers

Continued supply chain issues – longer lead times, labor shortages and price increases – are forcing companies to reevaluate how they buy and sell. Keep Reading

Haver & Boecker Niagara showcases new wares at MINExpo

The new F-Class vibrating screen features new technology, is built with lockbolts rather than welding and maximizes open area. Keep Reading

Haver & Boecker Niagara to highlight Pulse software at MINExpo

The company's vibration analysis software offers aggregate operations insights about equipment performance. Keep Reading

Haver & Boecker Niagara Ty-Wire screen media

Featuring a unique design that delivers as much as 80 percent more open area than modular polyurethane, Ty-Wire minimizes blinding and virtually eliminates pegging to increase screening efficiency and operational uptime. Keep Reading

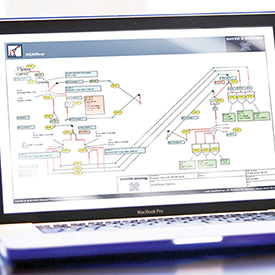

Haver & Boecker Niagara NIAflow

Haver & Boecker Niagara offers its NIAflow plant simulation software to help producers optimize quarry and mining operations. NIAflow analyzes existing or proposed processes, records plant statuses, monitors input, output and waste piles, and recognizes potential for plant optimization. Keep Reading