Haver & Boecker Niagara

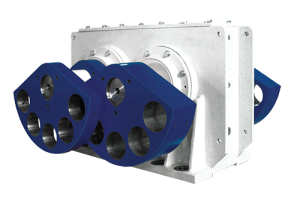

Haver & Boecker Niagara exciters offer improved screening performance

Niagara Exciters are engineered by Haver & Boecker Niagara to set the required stroke, frequency and exact static moment for each application. Keep Reading

Screening insights: How producers are riding the smart tech wave

Equipment suppliers share how the latest solutions are transforming screening operations and what’s ahead in technology. Keep Reading

How Nels Ostero keeps aggregate all in the family

A family-oriented, third-generation Canadian quarry operation keeps its commitment to quality through changing seasons. Keep Reading

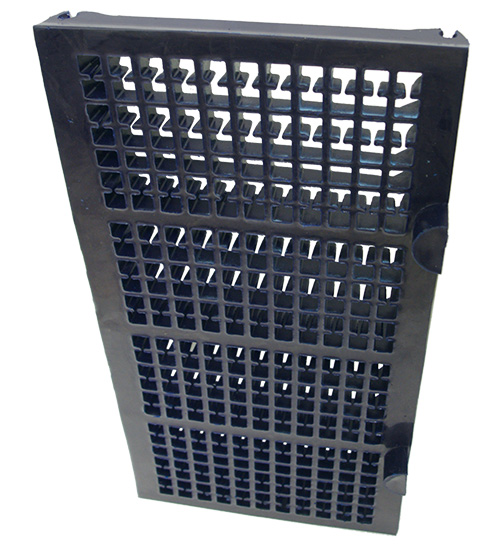

New screen media reduces need for rinse screen

Ty-Deck Ultra joins Haver & Boecker Niagara’s extensive line of Tyler engineered media including Ty-Max, Ty-Wire, Ty-Dura, Ty-Plate and the original Ty-Deck. Keep Reading

Haver & Boecker Niagara Pulse Vibration Analysis Service

The service helps customers achieve production targets, minimize unscheduled downtime and demonstrate sustainable improvements through online asset management. Keep Reading

Make the old new again, save money with refurbishments

With just four simple steps, manufacturers can update old screening equipment at nearly half the cost of purchasing a new machine. Keep Reading

Haver & Boecker Niagara XL-Class Vibrating Screen

The Niagara XL-Class vibrating screen combines advanced exciter drive technology with a wide body to offer high-capacity screening action at up to 15,000 tph. Keep Reading

How equipment suppliers are successfully providing virtual training

Despite the pandemic, equipment manufacturers continue to provide training and resources to aggregate producers – even in socially distanced times. Keep Reading

Haver & Boecker Niagara launches vibrating screen analysis service

The service will help customers minimize unscheduled downtime while achieving production targets, according to the company. Keep Reading