The X Series™ is designed to grind materials to high percentages passing 200 mesh (75 micron) and 325 mesh (45 microns) with throughputs of up to 40 tons per hour. When the X Series can be applied, benefits are convincing when compared to ball mills or air-swept vertical roller mills. Benefits include: high uptime – once installed, the X Series cage mill cage can be run continuously for long periods of time; low maintenance – regular wear part inspections are determined for each customer material and become routine to plan; simplicity of operation – once machine design parameters are determined pre-sale, electric motors and VFDs (Variable Frequency Drives) control the output product gradations; high range of acceptable feed size without compromising product yields – X Series cage mills are highly tolerant of a broad range of feed sizes; air classification or mechanical separation can be integrated into the cage mill system for ultimate output product control.

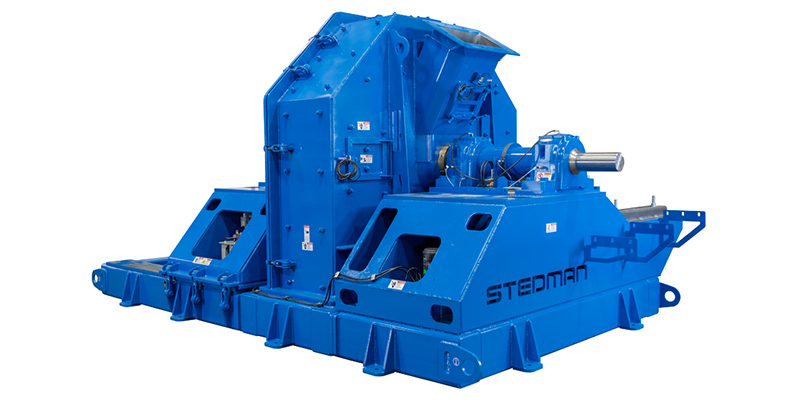

Stedman Machine Company’s Next-Generation Super Fine Grind Cage Mills

Photo: Stedman Machine Company

Previous Story