SKF is now offering manufacturing services for industrial gearboxes. According to the company, the services provide cost-effective solutions to refurbish and upgrade obsolete or damaged systems to quickly return them to service.

The company uses a systems approach to diagnose root causes of gearbox failure and prescribe technical remedies to implement proper fixes. The company’s process begins with an on-site inspection and initial diagnosis, which takes place before a gearbox is sent to one of its repair centers.

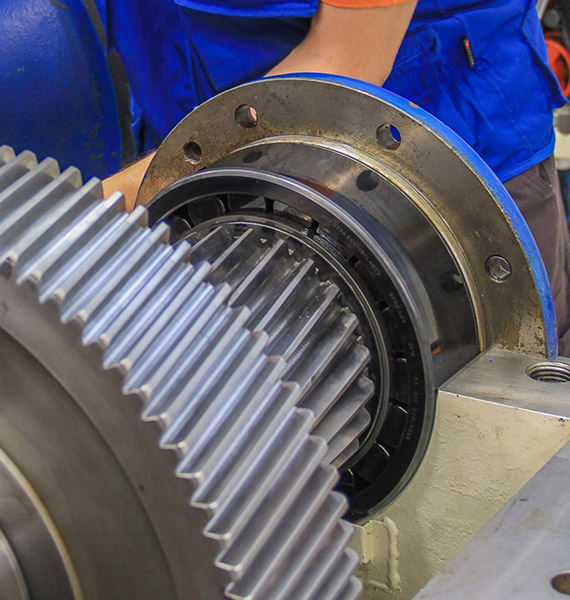

Once the repair center receives the gearbox, SKF service engineers disassemble, clean, inspect and analyze critical components, including gears, bearings, shafts and seals. The engineers use root cause analysis to pinpoint why a gearbox has failed, the company says.

According to SKF, the gearbox’s refurbishment is carried out as a complete machine renovation involving the replacement or reworking of parts and housings. In addition, the refurbishment process presents an opportunity for clients to upgrade with value-added design, engineering, components and precision machining.

Finally, once the work is completed, SKF performs final testing and installs the gearbox for a return to full productivity and efficiency. Cost-benefit analysis has shown significant cost savings may be achieved by remanufacturing a gearbox, the company adds.