Mine sites are home to significant water management challenges.

Whether a site deals with groundwater swells, nearby water sources, rain and snow accumulation, or overall mining waste processing – or all of the above – the safety and productivity of a mine come down to reliable and efficient dewatering across a variety of application needs.

For mining engineers, this means selecting a pumping system that’s built to handle the unique challenges the site faces. Choosing the right system isn’t just about addressing immediate dewatering challenges, though.

To ensure water management is effective for the long haul, mining engineers must evaluate a pumping system across a range of unique factors.

Assessing your site’s challenges

Mining sites can be harsh environments that are difficult to access and challenging to maintain. High environmental pressures, safety demands and overall productivity all factor into finding the right pump for a site’s needs – and they’re often considerations unique to mining operations.

When it comes to dewatering, consider these typical mining site demands:

■ Mine topography. Where is the water, and where does it need to go? How far underground is the water, and where does it need to be moved to? Is the water clean and being diverted to a close natural water source? The more linear and vertical feet of pumping required, the more extensive a dewatering system will need to be because not every pumping system will work as efficiently over longer distances.

■ Water volume/flow. How much water needs to be moved? Are the dewatering needs constant or occasional? Be specific when considering the gallons per minute or flow rate requirements of the application, as this is a major consideration when evaluating pumping options.

■ Water chemistry. What is the solids content of the water? Is the application moving naturally occurring minerals such as sand and rocks, or harsher elements like acid or waste? Solids not only affect the weight and volume of water management needs but can affect the equipment itself – because not all pumps are engineered to handle abrasive or corrosive elements.

■ Water quality. Does the water need to be treated? Mining operations in remote and dry locations often need to recycle the water they pump out. Others may be pumping out waste that must be treated to meet U.S. Environmental Protection Agency (EPA) regulations.

■ Mine size. How much space is available to accommodate the pump? Not all pumps are small, yet many mine sites have limited real estate to house a pumping system.

Is the pump located deep underground in a small area? Or, just 50 ft. below the surface? This consideration works together with another: the accessibility of the pump for service and priming.

Not all pumps are self-priming and service-free. If a mine site team needs to reach the pump to keep it operational, will they be able to?

■ Power options. In some cases, an electric-driven pump package may be the right choice for a mine. The heavy tanker trucks needed to refill a diesel pump package may result in too much wear and tear on some mine sites, making electric a smarter choice.

Still, if a mine site does not have power or the job is temporary, diesel is typically the best choice, as running power to the site may exceed the cost of operating a diesel pump package.

■ The overall natural environment and weather conditions. From sandstorms to blizzards, what type of rain, cold, heat and unexpected conditions might the site face?

Comparing system capabilities

A pumping system that’s designed to meet the unique demands mining operations face is more likely to keep running through every tough mining challenge. Finding the pump that works best for a site’s needs often comes down to comparing how today’s pumping technologies differ from one another, as well as how a site’s available power source can factor into selection.

Consider these typical pump system options:

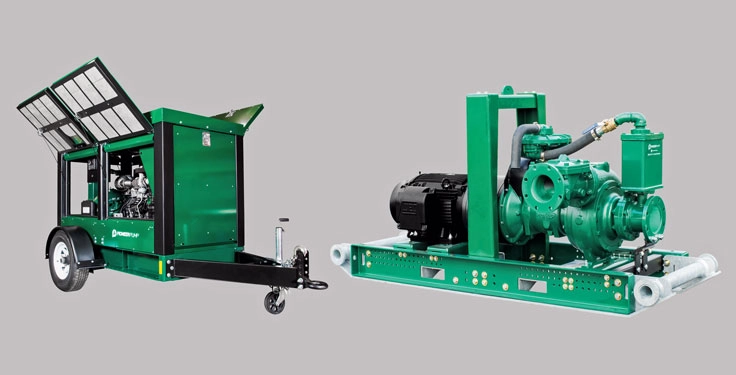

■ Surface pumps versus submersible and vertical lineshaft turbine (VLST) pumps. Surface pumps are designed to be used at ground level. Their rugged design and easy access make them ideal for wastewater disposal, reuse, slurries and tailings, as well as general dewatering.

Self-priming versions will continue to reprime automatically after initial priming, for less maintenance. The best surface pumps for mining applications will feature impellers designed with materials such as stainless alloys and high-chrome white iron that maximize resistance against abrasives.

Submersible and VLST pumps are available in custom configurations to meet a variety of demanding application requirements. Submersible turbines are typically paired with fully encapsulated or rewindable submersible motors, and VLST pumps are paired with a surface motor.

Both, however, can be used for most general dewatering needs. They can also be used to access nearby water sources.

Submersible pumps are often ideal for smaller mine sites where there is limited real estate to house a surface pump, as these compact pumps are out of the way and protected within the mine shaft.

A combined approach can also be taken, operating a submersible pump deep within the area being dewatered alongside a surface pump to move the water completely out of the mine.

■ Diesel- versus electric-driven pump packages. If electricity is available at the mine site, mining engineers will want to consider using either a diesel- or electric-driven skid and trailer package.

If the mining application requires varying duty points, an electric-driven package can offer unique flexibility, allowing the pump to meet the specific efficiency and performance requirements of each application.

Portable electric-driven pump packages are typically paired with variable-frequency drives so that multiple performance conditions can be achieved with one pump simply by adjusting the speed. This flexibility makes electric-driven packages a great choice for maximizing return on investment, because one pump can do the job of many.

Electric packages also offer environmental benefits by running clean, minimizing emissions and mitigating hazardous waste cleanup from leaks and other EPA regulations.

While electric-driven packages have some cost and performance advantages in certain types of applications, there are still circumstances when diesel-driven packages are the better choice. For example, consider the operating environment.

To use an electric-driven pump package, a mine site will need to have access to on-site power. Ideally, this power should run across the entire mine so the pump can be used in multiple applications – fixed or portable.

Still, access to power in all locations across a mine site that has a pumping need may not be practical or cost effective. In these instances, the profitability and simplicity of a diesel-driven package will provide more flexibility.

If site power is unavailable, a generator will be needed. This can add to a pump package’s initial cost. In this case, a diesel-driven pump package may be a lower upfront investment.

Luke Tucker is marketing strategist at Franklin Electric Co.