Inclined screens. Horizontal screens. Portable screening plants. Screen media.

Screening equipment was scattered throughout the expansive ConExpo-Con/Agg footprint, with brand-new offerings spotted in various places on the trade show floor. Here’s a look at some of the developments show visitors saw as they traversed areas in and around the Las Vegas Convention Center:

New horizontal model

An ESX series triple-shaft horizontal screen by Simplicity was on display in the Terex MPS booth. Terex MPS’s Russ Burns says the extended clearance between ESX decks is a feature that separates the series from traditional triple-shaft models.

“The most common complaint with these types of units is the spacing between the decks is often extremely tight,” says Burns, sales director at Terex MPS, which exhibited in the Silver Lot outside the convention center. “Operators are always looking for that skinny guy. Sometimes, they’re removing the top-deck media to get to the second deck.”

Now, operators have more clearance between the top and middle deck.

“Roughly 23 in.,” Burns says, “and 27 in. between the middle and the bottom. So, it gives you much more space for maintenance. It’s easier to get in there to look at the performance of the media that you have.

According to Burns, the ESX will find a particular home in the market.

“It is going to be geared more toward static-type applications where people really liked the horizontal unit but prefer to go incline in many cases, just because the space between [decks of] an incline is greater,” he says. “So, we’ve taken that feature from an incline and designed into a triple-shaft.”

Incline introductions

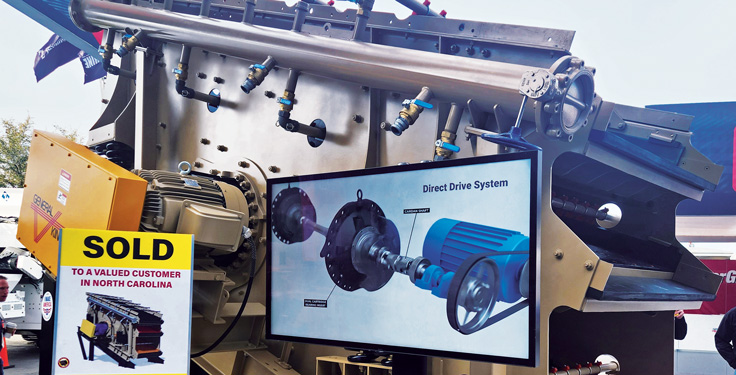

General Kinematics, which also exhibited in the Silver Lot at ConExpo-Con/Agg, showcased a new incline screen and its various features.

According to General Kinematics, features of its new incline model are less maintenance, extended bearing life, a cartridge-style mechanism and a non-pivoting motor base. A direct drive means no pivoting motor base is present that might cause premature drive belt wear, and dual crown decks for models 8 ft. and wider mean the screen media weight is less and installations are safer.

Another incline screen – Haver & Boecker Niagara’s F-Class model – was on display a short walk from the General Kinematics booth. Characterized as the company’s flagship machine, Haver & Boecker Niagara showcased the screen for the first time at any trade show.

The company’s Duncan High highlighted the benefits of the F-Class’s double-eccentric shaft assembly during a ConExpo-Con/Agg press conference.

“There’s very little shaking of the structure,” says High, process equipment technology manager at Haver & Boecker Niagara. “The other big thing from a productivity point of view is the double-eccentric shaft assembly gives you better stratification of the material.”

At the show, High also touched on the company’s ProCheck approach of finding solutions for customers.

“Generally, with the ProCheck approach, we will look at your machine visually as well as diagnostically to figure out how it’s running,” he says. “We’ll look into whether you need new processing equipment, new parts or could the service department help you.”

New media to explore

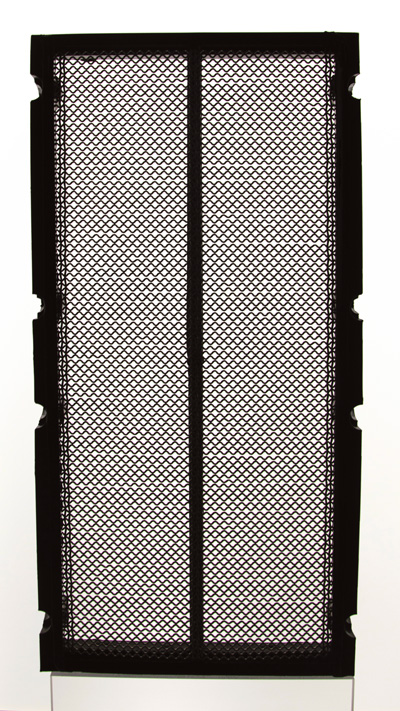

Inside the convention center, Polydeck put a spotlight on its new Ultraclean modular wire product whose benefits are experienced in sticky applications.

“It doesn’t lead to blinding,” says Trey Rollins, director of marketing and inside sales at Polydeck, which did a hard launch of Ultraclean at ConExpo-Con/Agg. “Basically, we redesigned the panel. There are other panels out in the marketplace like this, but what we’ve done is upgraded the design in a way that helps it be more efficient. There’s more open area in this than what you would see in a competitive panel.”

Rollins says Polydeck oriented Ultraclean’s wire horizontally so it mimics a wire screen’s performance.

“With competitive panels, the wire is run vertically over the panel,” he says. “[Ours] helps clean the material better. We’ve tensioned the wire across the bridge so you get more live action. That, again, helps to clean the materials.”

Ultramax, another screen media product Polydeck focused on at ConExpo-Con/Agg, is part of the company’s Rubberdex family of products.

A Polydeck goal with Ultramax is to equal or exceed the open area of wire cloth.

“It’s not considered an UltraMax panel unless the open area of that panel will meet or exceed the open area of wire cloth,” Rollins says. “The whole point of us launching this product is to compete directly with wire cloth.”

Rollins says the Ultramax panels Polydeck showcased at ConExpo-Con/Agg offer 56.5 percent open area.

“That’s 72 percent more open area than what you would get with a competitor panel,” he says.