The System Saver from Deister Machine Co. filters used oil without exposing it to the open environment, saving users time, money and oil in screening circuits. According to Deister, the system filters out harmful contaminants in the lubricating oil, allowing for reuse of the oil. The system extends the life of antifriction bearings in the lubrication system, the company adds, while reducing bearing replacement, system downtime and oil disposal costs. By extending oil change intervals through filtration, Deister says producers can justify the costs and enjoy the benefits of premium-grade synthetic oils. The System Saver is ideal for quick-pressurized filling of viscous oils, the company adds, saving time over gravity feeding.

Monitoring system applicable to screens

Metso’s cloud-based monitoring system covers stationary screening equipment. According to the company, its Metrics monitoring system offers improved safety, increased uptime and throughput – plus reduced maintenance of the unplanned variety. The system enables operators, controllers and service professionals to see real-time analysis of vibrating screen performance and bearing condition. Metrics is designed for intuitive operation, Metso says, as an easy-to-read screen dashboard with OEM insights makes it possible to quickly detect potential issues and take corrective action in time.

Customized solutions to elevate key metrics

Conn-Weld Industries demonstrates process solutions in action by, for example, getting more out of an 8-ft. x 16-ft. DD horizontal scrubber discharge screen. As Conn-Weld describes, a customized feed system ahead of a vibrating screen will increase wear life in addition to maximizing screening efficiency. A feedbox with a fixed or curved sieve, installed with the proper screen media, will offer benefits from a process standpoint by taking out some of the material before it gets to the vibrating screen, Conn-Weld adds. Throughput, therefore, is increased.

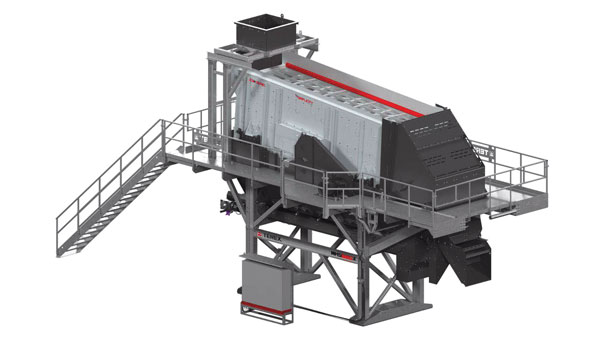

Modular screen plant embodies safety, sustainability

Simplicity, a Terex MPS brand, offers the MHS620X screen plant within its modular product line. According to Terex MPS, the MHS620X features a new “extra clearance” 6-ft. x 20-ft. ESX horizontal screen. The ESX provides increased space between decks, allowing for easier maintenance access to screen media while improving maintenance safety. Features of the MHS620X are an extra-heavy-duty I-beam frame, a rigid diagonal truss construction and a galvanized steel structure that includes walkways, stairs and guardrails. The MHS620X emphasizes safety, sustainability, ease of operation and streamlined setup, the company adds.