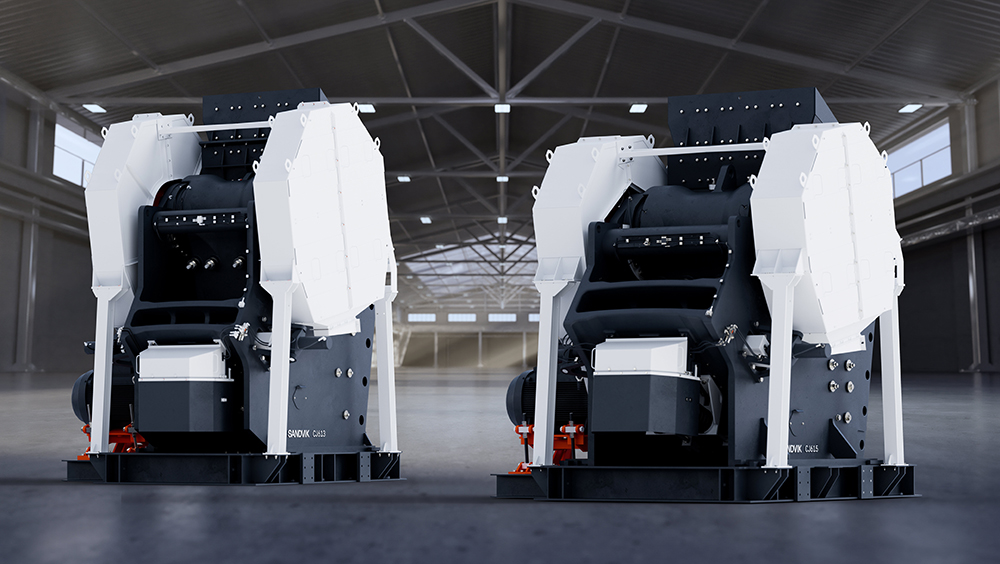

Sandvik launched a range of jaw crushers that offers new benefits in safety and performance.

The upgrades include a new hydraulic wedge setting adjustment, a synchronized retraction arrangement, an improved power pack, upgraded guarding and clear, role-based user documentation.

Additionally, Sandvik says its upgraded jaw crushers are manufactured with a welded mainframe and feature material quality improvements.

“Our new upgraded jaw crushers are now more aligned with the full Sandvik range,” says Martin Johansson, global product manager of jaw crushers at Sandvik. “They give our customers even more ability to secure safety, improve productivity and availability, reduce costs and accelerate sustainability with a partner they can count on.”

The jaw crushers are also equipped with Sandvik’s new ACS-j system that simplifies monitoring and control of lubrication, hydraulic settings and eccentric shaft bearing temperature. According to Sandvik, the system’s information is accessible through a web interface that provides customers with easy oversight and control of components and crusher metrics that help maintain optimal performance and availability through easy troubleshooting.

Related: Finlay adds jaw crusher to lineup