Four aggregate producers took part in an equipment and technology panel at last month’s Pit & Quarry Roundtable & Conference. Those who sat on the panel were Ronaldo Dos Santos (Anderson Columbia), Thomas Haun (Turner Staffing Group), Cody Ladd (Kraemer Mining & Materials) and Chris Williams (Capital Aggregates). The discussion here was edited for brevity and clarity.

P&Q: Describe your general approach to equipment and technology selection. Who are the people involved in the decisions, and how do you go about selecting?

DOS SANTOS: We have two different approaches. One is a more proactive approach. When we are doing the planning and budgeting, if we see some costs that are not trending the way we would like, that’s where we start the discussion with our plant managers and supervisors.

The reactive approach is once we set our goals, if we’re not achieving those goals, that might trigger some initiatives where we try to either change procedures or invest in equipment.

HAUN: When there are so many options out there, knowing which ones you want to bite off – whether that’s back office-related technology or technology at a plant or in the field – just making sure we have our priorities straight is probably the biggest thing.

From our end, it starts with [Turner Mining Group president] Keaton [Turner] and me. But I do think there is a leadership element to implementing any initiative or technology into a company.

Without buy in from the field, I don’t care what technology you’re trying to implement, if it’s not going to get utilized, it’s not going to be worth anything.

LADD: I’m interested in the financial incentive. We’ll look at the FPA (financial planning analysis) and if there is some sort of technology or something that’s unscheduled. Then the question for us is not what the ROI is; it’s what the IRR (initial rate of return) of it is.

We have somebody in finance and our CFO both involved in that analysis, as well as whoever is going to be touching and implementing that process. And if it passes all the financial checkpoints, at that point it becomes a question of what [Microsoft] Excel missed. We can run a couple different scenarios on that, and if at the end of all that we feel really comfortable, then we’ll move forward with a new process or technology. Otherwise, we try to stay well ahead of what needs rebuilds or what needs to be replaced.

WILLIAMS: When we talk about technology and advancement, I think there are two things: There’s the progression of how equipment works – upgrades, technology incorporated into existing technology to make things better for operators or further operation – and then there’s new and emerging things that are bigger.

Two different teams evaluate those. If we go to a trade show, we’ve got operations managers for each of our companies that will evaluate upgrades to existing equipment, and [they’ll] bring forth their proposals for how it justifies a purchase. Whereas [Capital Aggregates COO] Jamie [Jones] or I may spend a great deal of the trade show looking at the big advancements and if there’s a way for us to either partner with the manufacturer, or at least follow along to find out if it’s worth our exploration as a company.

P&Q: Where would you say your company has had some success on this front of late, whether it be a result of attending ConExpo-Con/Agg 2023 or from elsewhere?

WILLIAMS: The John Deere rollout of the 944 loader [was] revolutionary equipment in our space. It allowed midsize and smaller producers to get on board quickly. We’re able to very easily identify how it would pay for itself through the technology that was implemented and its design. Over time, we’re learning what does and doesn’t work with those new technologies.

HAUN: Where we have found the most success is actually back office-related. I say that because in our [Roundtable] breakout [session], there was a conversation about data and how difficult it can be to get data from the field. We agree, and we pivoted focus elsewhere where we have really good data.

We’ll do things like optimize our recruiting process to make sure we get the right number of applications every year. We’ll also think about how we are managing our equipment from a remote perspective. We think a lot about software that is back office-related, because that tends to be an easier implementation than something that would have to be in the field.

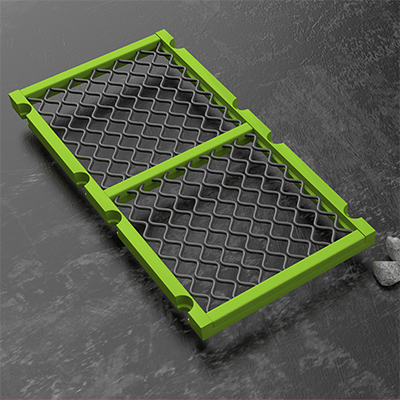

DOS SANTOS: When we were planning the expansion of our Tejas Quarry in Texas, we were able to assess different type of log washers. We identified one that was unique to North America, and we were very successful in producing good-quality material with that specific equipment.

On the other hand, we also learn from our failures. We tried to implement quality control using imagery. And although the technology is very developed, we couldn’t make it fit our needs. It’s good technology, but we couldn’t implement that in a way that would add value to our business.

P&Q: Let’s talk about AI. Some in the industry say they’re still figuring out where it’s going to apply. What has your experience been in this space?

LADD: It has its place right now. I won’t say what roles specifically, but a couple of us tried to do all of our financial models with Chat GPT and it wasn’t bad. We also tried to put together a pitch deck with it, and we tried to see how far we could go. We tried to write a contract with it. They all needed a lot of work afterward.

Where it’s come in handy for us is a job description. Now, you can just go to Chat GPT and say: ‘Write a job description for a mergers and acquisitions professional,’ and it comes out great.

HAUN: You have a tool at your disposal where you can get educated quickly. We have a young recruiter on our team, who has just become an absolute stud in a year. She did it by learning things through Chat GPT. I give her a ton of credit for that.

WILLIAMS: For us, right now, back office is where the value is. Small things like invoice distribution. Managers can automate that process, and we’re taking it out of an individual’s hand to manually forward every invoice that comes into the office. It starts there, and now we’re waiting for other opportunities for growth.

DOS SANTOS: Right now, we have a pilot project with sensors for vibration and temperature. The software that manages the sensors in real time is a learning machine. It detects failures and provides recommendations. I found it very interesting the amount of data you can have access to and the software to process that data. That’s important, because you wouldn’t have enough time to do that.

Related: Turner Mining Group’s Haun joins ‘Drilling Deeper’ podcast