P&Q ran into TerraSource Global’s Kevin Hambrice several times in the first quarter – first at the Pit & Quarry Roundtable & Conference and later at SME’s MINExchange. The magazine finally did a one-on-one with Hambrice at AGG1, where he reflected on his trade show experience and what he’s observing in the market.

What sorts of things are you hearing from customers these days? What are they telling you, and what are they asking of you?

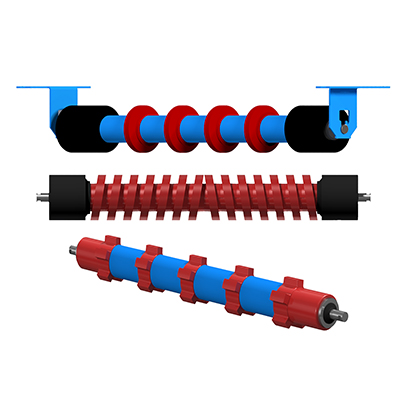

We’re in the crushing, feeding, screening and separation business when it comes to minerals. There are two common themes we’re hearing.

Everyone is focused on safety. So, [it’s] what are we doing to make our equipment even more safe?

The other thing is what are we doing to make our equipment automated? Sensing technology and making equipment smart is important to them. We’re all working with less people, so we need reliable equipment.

How challenging is the sensor front in our industry, putting sensors on equipment? One thing we’ve heard of late is that there’s been some pushback on sensors because of the challenging nature of our environments.

You would think on the outside that it’s maybe complicated and we’re not there yet. But if you look at your motor and your big bearing people, they’ve already got this ready to go off the shelf and plug and play into a system. It’s already been tried and tested.

[When] you think about tough equipment, the industry is ready. Equipment suppliers are ready, and our end users want to be safe and automate. So the time is now.

How are your customers managing the information that’s pouring out of their equipment? That was a theme we heard coming out of ConExpo-Con/Agg last year, and we’re seeing more technology come into the industry that’s tied in with equipment. Also, how are manufacturers and dealers making sure end users ultimately utilize the information put out?

Some of this is just pure data acquisition. You’re just looking at the information. In some cases, you’ve got pure control as well as that acquisition.

There’s lots of different platforms out there. The big control systems companies like Rockwell [Automation] and Honeywell have things ready to go. A lot of it is a little bit of a culture shift or a paradigm shift because they’re used to working on a manual piece of equipment, and now they have information at their fingertips. It’s an interesting time.

What do the next five or 10 years look like for the industry? What are your thoughts?

If you just look at the Baby Boomer population versus [Generations] X, Y and Z, that Y and Z is that generation that’s coming to work that we’ve got to equip. That generation is smaller, so if you just do some quick math, you find out quickly that we don’t have enough people to fill the gaps.

So, what does that mean? We need capable equipment. We need resources. We need automation. The timing is now, and if we don’t act quickly we’ll be behind. We won’t be able to even supply what the demand is asking for.

Related: Drilling Deeper Episode 15: Insights from Capital Aggregates, TerraSource Global & TCI Manufacturing