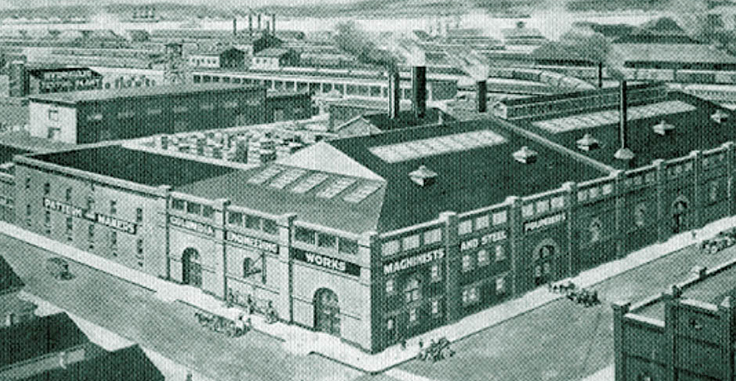

Columbia Steel, which makes replacement wear parts for the mining, metal recycling and power industries, is celebrating its 120th anniversary in 2021. Columbia Steel president and CEO Martha Cox paid P&Q a visit to reflect on her company’s history and discuss the change she’s seen take place within the aggregate industry. Cox, who’s been with her third-generation family-owned business for 49 years, took over as Columbia Steel’s leader in 2012 after her father, Bud Bird, steered the company through the second half of the 20th century.

What did you learn from your father growing up that prepared you for your leadership role at Columbia Steel?

He passed away [in May], but I did have the privilege of working with him for many years.

Character counted for him. All of the comments we’ve gotten since his passing were that he was a person of integrity, how his word was his bond. He also kept his door open and didn’t try to do everything himself. He called all of the shots, but he was open to suggestions and hearing about issues customers were having. His philosophy had always been to hire good people and let them do their job.

Most of our managers and senior people came up through the ranks. They felt empowered that this company was their company, and they would apologize for saying ‘this is their company.’ But I appreciate that they’re taking that much ownership in it.

What are the most noticeable differences you see in the aggregate industry today versus when you started?

There has been some consolidation, even with Martin Marietta’s purchase of [Lehigh] Hanson West. But I’m encouraged because there is still opportunity for Columbia to provide value.

The crushers we are using and the design of them continues toward more horsepower, larger machines and more output for the customer for the same footprint. But this means increased liner life, and that’s where we come in. With alloys, we continue to develop more materials for longer lasting. The need for the product is consistent, as long as we are building roads and airports.

Developments in the supply chain have become somewhat problematic this year. What are you seeing from your seat at Columbia Steel?

There are two issues. One is transportation. To that end, I think there is some benefit to buying domestically. We export about 35 percent of what we produce. Booking space on ocean cargo can be challenging. It can take an extra two or four weeks to get space on a ship going the way you want it to go.

Most of our materials are sourced locally. We recycle 50 tons of steel scrap a day and 200 tons of sand a day. The sand comes from the state of Washington. Some alloys only come from overseas, but we’ve secured sources for those.

The other part is pricing. Customers want to know what their operating costs are going to be six months down the road.

How is Columbia Steel celebrating its 120 years?

We have a big picnic planned in September, as we are thinking we can do things socially together by then.