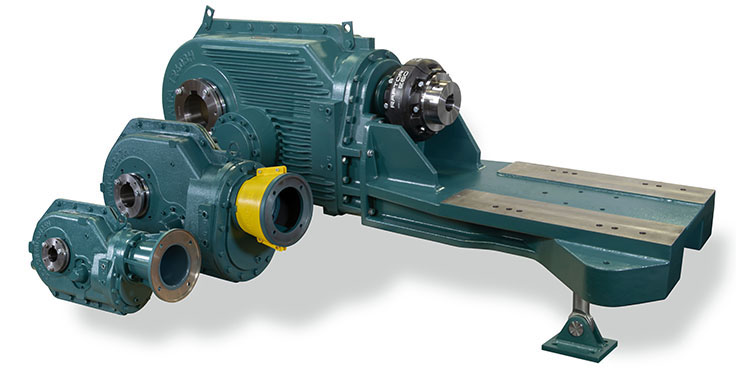

XMiner industrial gear units are designed for the demands of aggregate applications – including conveyor systems, crushers and apron feeders. Built on the X.e series platform, SEW-Eurodrive says XMiner units are available with local engineering, stocking and assembly in Wellford, South Carolina. As SEW-Eurodrive describes, the units provide several benefits to operators, including reduced weight and cost thanks to a high power density, a cooling system that eliminates the need for cooling alternatives, reduced inventory and spares, and local engineering and application support for proper sizing.

Motorized torque-arm enhancements elevate gear reducer performance

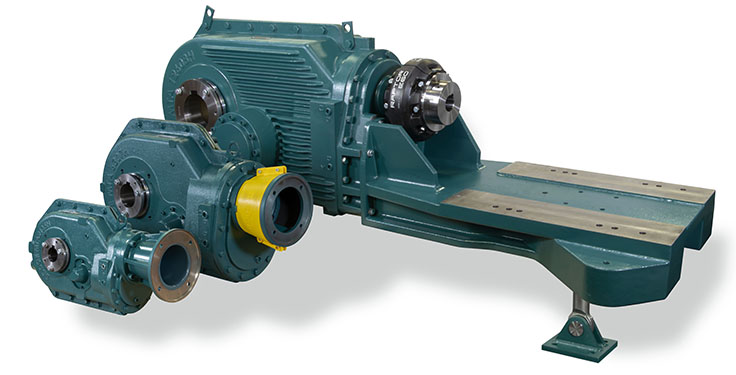

Dodge Industrial’s motorized torque-arms (MTA) are the only AGMA-rated direct-drive reducers, according to the company. Dodge’s MTA lineup is now larger and offers new capabilities. Larger 9, 10 and 12 reducers, for example, support up to 329,000 inch-pounds of torque. Additionally, assembly packages with reducers sized 7 to 12 and Atlas Adapter support large foot-mount motors 60 hp and above, reducing the need for spare motor inventory by allowing the use of standard foot-mount motors in sizes not commonly stocked in C-face styles. Dodge says C-face safety input adapters enable access to the coupling through a split cover to eliminate the need to remove the motor.

Monitor machine health digitally

Regal Rexnord Corp.’s next-generation Perceptiv intelligent reliability and maintenance solution is designed for condition monitoring and predictive maintenance in industrial manufacturing. This next evolution of the Perceptiv ecosystem offers customers a unified platform to meet growing reliability needs, the company says. Perceptiv intelligence uses in-field sensors and gateways to monitor machine health. Collected data can be sent to a customer’s on-premises system through industrial protocols, or to the Perceptiv web platform for online viewing. Through the web platform, Regal Rexnord reliability engineers can analyze data to provide customers with recommendations on how to extend equipment life and reduce unplanned downtime.

Solution for heavy radial and axial loads

skf spherical roller bearings, available from Motion, offer a high-load-carrying capacity and the ability to accommodate misalignment, helping to reduce maintenance costs and extend bearing service life. The product line is designed for applications such as vibrating screens, conveyors and gearboxes. Motion says SKF’s three-barrier solution – a sealed spherical roller bearing with three barriers to block contaminants – is a solution for harsh operating environments.

Related: Regal Rexnord showcases products, company performance at media event