Philippi-Hagenbuch is now using SSAB Hardox HiTemp steel in its customized Hot Slag Bodies, which are part of its HiVol Truck Bodies lineup. According to the company, the new steel is designed to withstand extreme temperature environments and will reduce necessary plate thickness while maintaining the product’s service life.

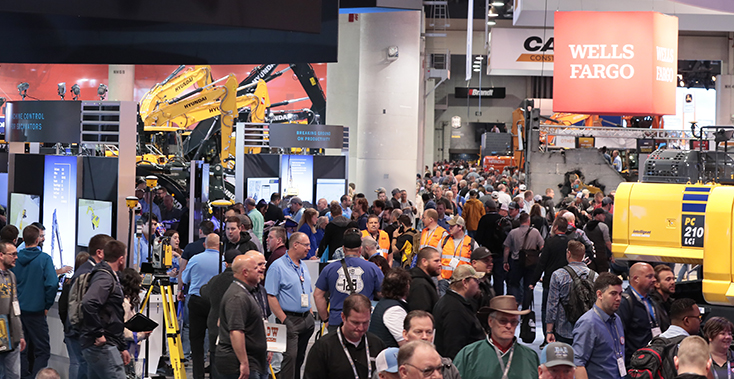

Philippi-Hagenbuch made this announcement at ConExpo-Con/Agg, which is taking place March 10-14 in Las Vegas.

“In the past, steel mill clients requested a unique HiVol truck body to haul hot slag,” says Josh Swank, vice president of sales and marketing for Philippi-Hagenbuch. “Our engineers responded with the Hot Slag Body. Now, with the new HiTemp steel from SSAB, we can provide the same strength and durability with less steel, maximizing payload potential and providing our clients with a better product.”

Philippi-Hagenbuch’s Hot Slag Body contains two components: an exoskeleton superstructure, which does not come in contact with molten material, and load containing pieces that do. These pieces form an overlapping structure that is loosely strapped around the body of the exoskeleton to contain the hot slag during operation. According to the company, this design allows for differential expansion and contraction, where a traditional body would buckle under such extreme heat.

In addition, the new HiTemp material improves the wear-resistant properties of a 450 Brinell steel, currently used in the Hot Slag Body. It’s capable of transporting materials in excess of 1,200 degrees Fahrenheit, the company adds, which allows the use of a thinner plate without jeopardizing the product’s service life.

Philippi-Hagenbuch, headquartered in Peoria, Illinois, has been building equipment for off-highway haul trucks since 1969.

For Pit & Quarry’s full coverage of ConExpo-Con/Agg 2020, visit our show page with the latest news, features and developments in equipment and technology.