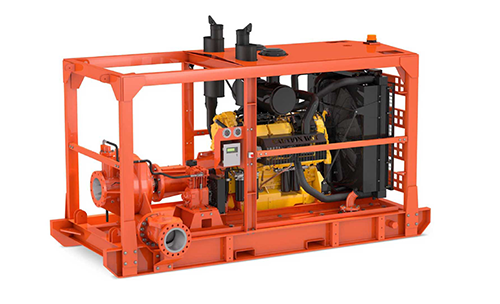

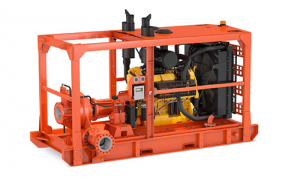

Xylem debuted a dewatering pump that was developed to increase efficiency, cut costs and minimize downtime for its mining and construction customers.

Designed to meet the unique demands of deep-mine and high-pressure water transfers, Xylem says the Godwin HL270M Dri-Prime pump reduces the need for multiple pumps in series while lowering energy consumption, simplifying operations and maintenance, and minimizing premature wear.

“Meeting the evolving needs of our customers is paramount,” says Mike Ramos, global product manager at Xylem. “The Godwin HL270M meets the unique demands of deep-mine and high-pressure water transfers. It allows our customers to go deeper and further while making operations more efficient, sustainable and safe.

“This product is also a great example of sustainable business being smart business,” Ramos adds. “The pump uses less power, reduces the need for multiple pumps, minimizes premature wear and offers longer life between repairs.”

According to Xylem, the Godwin HL270M delivers a maximum head of 984 ft. and flows of up to 4,400 gallons per minute. The pump also delivers hydraulic efficiency of up to 70 percent through its enclosed impeller, the company adds.

The pump is available in diesel- and electric-drive packages. Xylem says it will also be offered as a retrofit package for installation on existing customer-owned pumps.

Additionally, Xylem says the pump is available with two standard material options – all duplex stainless steel as the primary offering and an option for cast steel pump casing paired with a duplex stainless steel impeller.