Metso Outotec complemented its line of mobile and modular stationary crushing solutions with a sizer option specially designed for soft ore and aggregate applications.

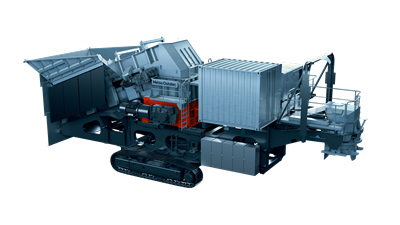

The new additions to Metso Outotec’s mobile Lokotrack product line are equipped with Komatsu’s sizer technology, and they’re available in five models ranging from 500 to 4,500 tph.

Metso Outotec’s recently launched modular FIT crushing stations are also available with sizer configurations. Both the mobile and modular solutions were engineered in collaboration with Komatsu.

“New concentration technologies and strict environmental norms make it economically viable to process such deposits and stocks that were not possible to handle profitably earlier,” says Julius Mäkelä, vice president of mid-size and mobile crushers at Metso Outotec. “However, the characteristics of soft ores like low abrasiveness and high moisture content require a different equipment configuration than when crushing hard ore. To provide leading solutions for our customers processing soft ore, we’re now combining our expertise in mobile and semi-mobile crushing with Komatsu’s sizing knowhow.”

Similarly, Komatsu is excited about the opportunity to partner with Metso Outotec.

“Komatsu’s Joy sizers are well known in the industry, and they’ve proven their efficiency and reliability in various applications,” says John McCarthy, sizer product manager at Komatsu. “The combination of Metso Outotec’s Lokotrack and FIT station with our sizers provide a unique and superior solution for soft ore and rock crushing.”

Additionally, Metso Outotec says it can provide a truckless solution from the quarry to the concentrating or cement plant when combined with the Lokolink and conveying systems.