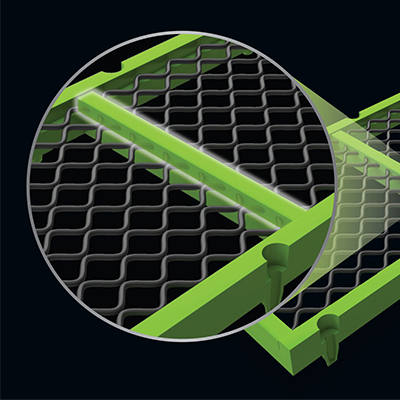

Metso expanded its MX wear parts offering to large cone crushers with MX for cones.

According to Metso, the new MX offering is designed to maximize wear part lifetime in secondary cone crushing applications for mining and quarry operators.

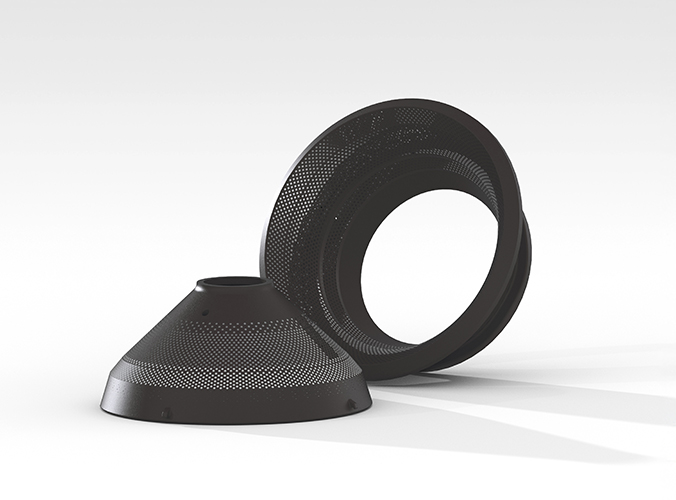

“MX for cones represents another step forward in the MX offering, addressing customer demand for hard-wearing solutions to reduce frequent parts changeouts,” says Rafael Yanata, product manager of mining crushing solutions at Metso. “This technology particularly meets the needs of large cone crushers from the Nordberg HP series and MP series.”

The Metso-developed inserting technology helps to maintain the optimal wear profile for longer by ensuring better liner utilization when compared to standard manganese liners, the company says. MX for cones can provide up to double the wear life in secondary crushing applications, Metso adds.

“As experts in crusher wears, Metso is committed to continuous development in crusher wears solutions for a full range of customer applications and needs,” says Jarkko Leppänen, vice president of mining crusher wears at Metso. “Designed, engineered and manufactured in-house, MX for cones is backed by Metso’s strictest quality standards and decades of expertise.”