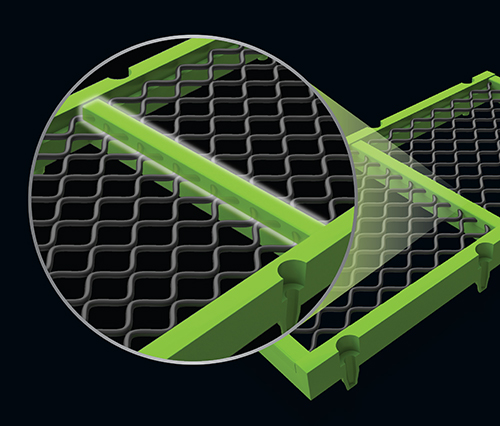

Major introduced a polyurethane strip variant for its Flex-Mat Modular series.

According to Major, the variant increases the screen media’s durability, extending its lifespan and effectiveness in wet and corrosive environments.

“While most screen media provide excellent durability, we noticed accelerated wear in some corrosive applications,” says Kevin Laporte, R&D manager at Major. “We immediately began testing to create a corrosive-resistant alternative we could develop into a new polyurethane variant. The new polyurethane strips would allow these specialty operations to benefit from Flex-Mat’s productivity-boosting qualities while still maximizing uptime.”

As Major describes, the polyurethane strip features greater chemical stability to improve performance in alkaline, acidic and wet environments such as limestone operations. The strips are available for the Flex-Mat Modular D, S and T series.

The variant is not intended to completely replace the standard polyurethane, Major says.

“The advanced [polyurethane] strips aren’t meant as a complete replacement for standard polyurethane,” says Ian Edwards, vice president responsible for global sales at Major. “Instead, they’re a special-order option for screen media going into harsh environments. The best use of the advanced [polyurethane] strips is when operations are screening corrosive or wet materials or when the operation notices their polyurethane is breaking down faster than the steel wire. In most cases, the standard polyurethane strip option continues to perform optimally for our customers.”