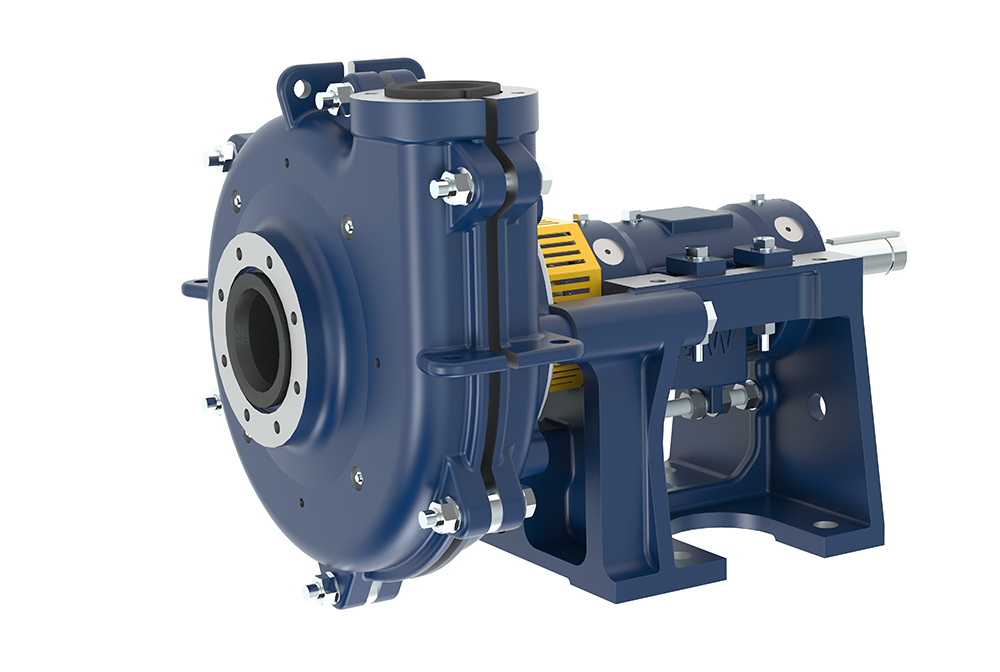

KSB GIW launched the GIW LCC Gen2 slurry pump series, a redesigned and upgraded version of its GIW LCC line.

Designed for Class 1 to 3 slurry applications, the company says the GIW LCC Gen2 maintains proven hydraulic performance while adding a modern design that improves maintenance access, extends service life and lowers total cost of ownership.

The GIW LCC Gen2 series retains the hydraulic performance of the first-generation GIW LCC while introducing upgrades in serviceability, reliability and spare parts compatibility. Key updates include a front pullout shaft seal design allowing seals to be changed without removing the bearing assembly; threaded flanges for easier piping connections; and zinc-plated fasteners for longer service life.

A more robust bearing assembly increases durability in demanding applications, KSB GIW says, and the expeller can now be added or removed without altering the bearing assembly piping or other major components.

“The GIW LCC Gen2 was developed with direct customer feedback to make an efficient, reliable pump even easier to own and operate,” says Kevin Pike, product manager at KSB GIW. “Every aspect of the redesign – from tool clearance and fastener access to integrated lifting points – was carefully considered to deliver a truly maintenance-friendly pump that cuts downtime and ownership costs.

“In the end, we had a great combination because we had a new and improved pump with a 40-year track record of performance and reliability,” Pike adds.

The GIW LCC Gen2 series is available with three wet-end configurations that share the same mechanical end, allowing operators to tailor pumps to their process conditions.

The GIW LCC-R Gen2 features a rubber-lined wet end that can deliver up to twice the wear life of metal in the right conditions, the company says. The GIW LCC-M Gen2 and GIW LCC-H Gen2 use Gasite 28G high-chrome white iron to provide wear resistance and long service life in abrasive duties.

Also, most major wet-end parts are cross-compatible between GIW LCC Gen1 and GIW LCC Gen2 pumps, helping customers streamline spare parts management and reduce inventory costs.

The new pumps will roll out in phases across North America. The GIW LCC-R Gen2 will be available beginning Sept. 30, followed by the GIW LCC-M Gen2 on Nov. 30 and the GIW LCC-H Gen2 on Dec. 30. Quick-ship inventory of core sizes is expected in the second quarter of 2026, with full availability by midsummer 2026.

“KSB GIW has combined decades of slurry pump expertise with customer feedback in engineering the GIW LCC Gen2,” Pike says. “The result is a pump series that offers a great mix of durability, affordability and useful features. With support from KSB’s global manufacturing network, customers worldwide can soon count on fast access to parts, service and inventory.”

Related: How pump manufacturers are taking measures to meet producer needs