FULL HANDBOOK

Chapter 1: Industry Overview

Chapter 2: Geology & Site Selection

Chapter 3: Drilling & Blasting

Chapter 4: Excavating & Loading

Chapter 5: Hauling

Chapter 6: Crushing & Hydraulic Breaking

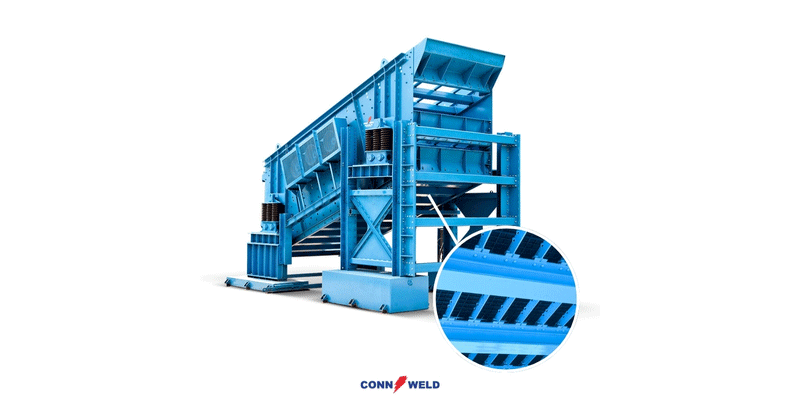

Chapter 7: Screening

Chapter 8: Washing & Classifying

Chapter 9: Conveying & Material Handling

Chapter 10: Loadout & Weighing

Chapter 11: Safety & Health

IN THIS CHAPTER

Material Uses

Estimates are that between 70 and 85 percent of crushed stone is used in the construction of roads, buildings and community infrastructure, with the remaining materials used in agriculture, by the chemical and metallurgical industries and for a variety of specialty applications.

These raw resources are indispensable to the maintenance and development of rural and urban environments. The construction of a new house, for example, requires an average of 400 tons of aggregates. Foundations, concrete blocks, bricks, mortar, roofing shingles and wallboard all require aggregates as a basic ingredient.

Additionally, tens of thousands of tons of crushed stone are needed for the construction of one mile of a four-lane highway.

Minerals provide the basic resources for homes, appliances, cars, electricity, communications and even modern medical care. Without minerals from crushed stone, there wouldn’t be the modern necessities that make lives safe, comfortable and productive.

In fact, minerals from crushed stone are so important in everyday life that demand has grown dramatically as society has become more complex. Americans use an average of 10,000 lbs. of crushed stone each year. Although most people know where to buy the things they want, they seldom know or even consider the source.

PRO TIP

Plan quarries near demand centers: Minimize transportation costs by sitting operations within 25 miles of the markets they serve.

Each year, the nation mines and produces minerals to manufacture cosmetics, medicines, cat litter, soaps, plastics, fertilizer, bricks and building materials, magazines, automobile tires, wallpaper, glue, ceramics and other essentials.

Increasingly, crushed stone is becoming a critical tool to protect the environment. Erosion-control programs require stone to prevent sediments from clogging waterways. Water and sewer facilities use stone and sand for filtration systems. Utility power plants use crushed limestone to reduce the harmful sulfur dioxide that produces acid rain.

With this economic pull toward the marketplace, mining of aggregate resources can be defined as an urban land use. Typically, this means mining activities exist within the urban fringe, where competition for undeveloped land is high and where there is considerable development activity.

Here are some examples of minerals Americans use every day:

- Bauxite. This is a naturally occurring mixture of aluminum hydroxides and mineral impurities. Its uses are important to the manufacture of refractories, ceramics, cements and flame retardants.

- Feldspar. It’s the most abundant mineral derived from igneous rocks, occurring in a variety of forms and mixtures. Feldspar is used in the production of ceramics, pottery, insulators, glass and latex fillers.

- Granite. Massive quantities of stone products will continue to be required for airports, road systems and key building projects. Granite is used in the building of roads, schools, hospitals, churches, houses and other modern construction.

- Kaolin. Also known as “china clay,” kaolin is a white aluminosilicate widely used in paints, refractories, plastics, sanitary wares, fiberglass, adhesives, ceramics and rubber products.

- Limestone. A sedimentary rock composed mostly of the mineral calcite and comprising about 15 percent of the earth’s sedimentary crust, limestone is a basic building block of the construction industry and the chief material from which aggregates, cement, lime and building stone are made.

- Mica. A platy mineral occurring in a variety of complex hydrous aluminosilicate forms with differing chemical compositions and physical properties, mica is used in cosmetics and electronic applications, as well as joint cements and sealers and oil well drilling muds.

- Sand. Sand ranges in size from 0.02 to 2 mm. It’s one of the principle elements used as aggregates in portland cement concrete, mortar, plaster and other building materials. It is also used in the manufacture of glass and fiberglass, sand traps, landscaping and as an abrasive for cleaning buildings and structures.

- Shale. Shale is a fissile rock compound made up of a variety of clays and other fine-grained rocks that are used in the manufacture of brick, drain tile, vitrified pipe, quarry tile, flue tile, conduit, pottery, stoneware and roofing tile.

Sand and gravel are common minerals resulting from the erosive forces of water, wind and ice. In fact, silica, the basic constituent of sand, is the second-most occurring element in the earth’s crust after oxygen.

Unlike crushed stone, which results from a manmade process, sand and gravel are generally found in river and stream valleys where they have been deposited by water, as well as in ridges and hills where they were left behind by receding glacial action and subsequently altered by erosive forces.

In their natural state, sand and gravel are usually loose, easily handled and – being composed of a range of grain sizes – are readily compacted while retaining good internal drainage characteristics, making them a preferred material for fills and as a base course for pavements and other structures.

When combined with a portland cement binder, sand and gravel become the principal ingredient in an unusually strong and long-lasting construction material: concrete, whether used in its plastic state and placed in forms, or precast as pipe, block and other structural components.

When combined with asphalt, sand and gravel become the aggregate forming the major element of asphaltic concrete, which is widely used as a paving material.

While some other materials can also be utilized as aggregates, sand and gravel are most commonly used for these purposes. In parts of the U.S., sand and gravel are the only economically viable sources of aggregates. As a natural deposit material, they are a valuable resource where they are relatively close to locations where aggregates may be needed for a broad range of uses.

Operations

Today, many quarry operators are typically involved in their communities.

They belong to neighborhood councils and participate in business and education partnerships. With a long tradition in community commitment and as conscientious land managers, responsible producers understand and respect the laws that regulate the industry.

Federal, state and local agencies work with producers to ensure safety and avoid environmental degradation. Often, crushed stone producers must obtain dozens of permits to operate in accordance with the many federal, state and local regulations.

Definition

Reclamation: The process of restoring mined land to a condition equal to or better than before operations began, often repurposing quarries into parks, lakes, housing or wildlife habitats.

Reclamation for an aggregate operation’s next use has been an integral part of ongoing management plans for decades. In most states, producers are now required to return the land to a like or better condition than when the operation started. Implementing a reclamation plan commonly begins at startup, with special attention given to programs such as wildlife habitat development and land contouring.

The results of successful reclamation can be seen in wildlife refuges, community parks and lakes, golf courses, housing subdivisions and shopping malls throughout the U.S.

Mining engineers, geologists, hydrologists and environmental experts typically work together to develop the best methods for controlling dust and noise, assuring overall regulatory compliance while producing quality construction aggregates.

Modern mining techniques are based on the latest advancements in technology. Software is commonly used to design the most efficient methods to mine the minerals necessary to produce high-quality crushed stone. Software is also an integral part of quarry blasting to assure minimal noise and vibration.

As technology advances, more aggregate operations are being automated and plants can run remotely.

PRO TIP

Leverage automation: Incorporate remote operation and advanced plant controls to improve efficiency, safety and compliance.

Producers maintain a strong and unwavering commitment to safety and health at workplaces, too, as each company must comply with stringent federal, state and local safety and health regulations. Safety and health training programs help to develop a knowledgeable workforce capable of recognizing, analyzing and avoiding inherent hazards of work environments.

Producers recognize that the earth’s resources are finite and that environmental stewardship is necessary to preserve the potential for a quality of life for future generations. To that end, producers must not only meet all established environmental regulatory requirements, but, where possible, they must do better than regulations require.

Leading producers regularly work with community leaders and citizen groups to develop plans for appropriate uses of the land once mining operations are completed. These plans naturally look out for the community’s best interest, as this will result in the highest land values.

Recent technology advancements have made possible the design of aggregate production facilities capable of assuring compliance with all regulations. More importantly, though, the absolute necessity of community acceptance has been the primary reason producers have adopted state-of-the-art technology in operations.

FULL HANDBOOK

Chapter 1: Industry Overview

Chapter 2: Geology & Site Selection

Chapter 3: Drilling & Blasting

Chapter 4: Excavating & Loading

Chapter 5: Hauling

Chapter 6: Crushing & Hydraulic Breaking

Chapter 7: Screening

Chapter 8: Washing & Classifying

Chapter 9: Conveying & Material Handling

Chapter 10: Loadout & Weighing

Chapter 11: Safety & Health

IN THIS CHAPTER

Use the page numbers to continue reading, or select a section / chapter above.

&uuid=(email))

&uuid=(email))