The Pit & Quarry University Handbook is an educational resource that offers comprehensive lessons covering the entire aggregate production process from start to finish, highlighting new technologies and enhanced procedures within each branch/category of the aggregates industry.

FULL HANDBOOK

Chapter 1: Industry Overview

Chapter 2: Geology & Site Selection

Chapter 3: Drilling & Blasting

Chapter 4: Excavating & Loading

Chapter 5: Hauling

Chapter 6: Crushing & Hydraulic Breaking

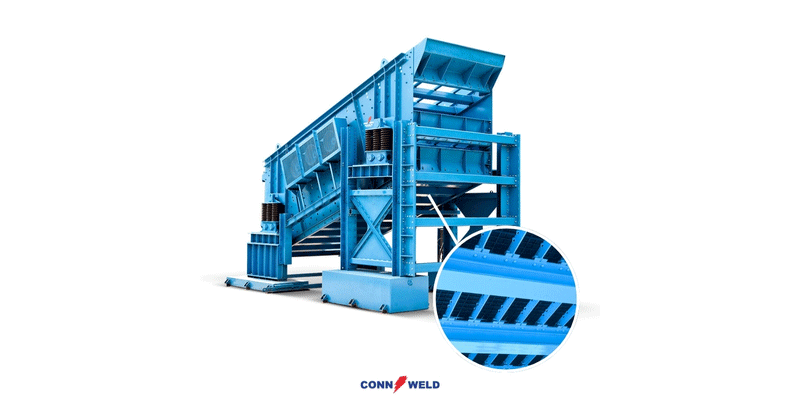

Chapter 7: Screening

Chapter 8: Washing & Classifying

Chapter 9: Conveying & Material Handling

Chapter 10: Loadout & Weighing

Chapter 11: Safety & Health

IN THIS CHAPTER

The crushed stone, sand and gravel industry in the U.S. – known as the construction aggregate industry – is made up of producers who provide materials essential to the nation’s quality of life – without which virtually no modern infrastructure could exist.

Unfortunately, even in 2025, the public knows relatively little about the aggregate industry, which produces about 2.4 billion metric tons of vital basic materials each year. These aggregates are used in every sector of the built environment – residential and commercial construction, surface transportation, civil work and environmental protection. The total value of construction aggregates produced in 2024 was about $37 billion.

Crushed stone accounts for roughly 1.5 billion metric tons each year, with about 1,400 companies producing stone at about 3,500 quarries in the U.S.

SAFETY TIP

Prioritize safety training: Regularly train employees to identify and manage hazards, building a skilled workforce that exceeds regulatory requirements.

Sand and gravel producers produce and ship about 920 million metric tons each year. An estimated 3,400 companies operating 6,500 pits account for this output.

In terms of jobs, the construction aggregate industry employs more than 104,000 people in the U.S. across a variety of roles. The industry employs accountants, business professionals, chemists, communications and PR professionals, economists, electricians, equipment operators, estimators, engineers, environmental scientists, mechanics, office personnel and professionals dedicated to safety and sales.

According to a Phoenix Center study, the industry supports $171 billion in national sales and $55 billion in national earnings

The Industry’s Rise

U.S. aggregate production increased steadily from the 1950s onward, driven by post-World War II suburbanization and construction of the Interstate Highway System. Additionally, more than 95 percent of asphalt pavement and more than 80 percent of concrete sidewalk is made up of aggregates.

Historically, about 40 percent of the construction aggregate market has been in road and other transportation-related projects. The remaining 60 percent split evenly among residential construction, commercial construction and other public works.

Those proportions changed somewhat during the Great Recession that began in 2007, but aggregate production climbed steadily until the early 2020s before slowly declining in the middle part of this decade.

The 1960s, ‘70s and ‘80s brought more demand for aggregates due to the requirement to maintain and upgrade the federal highway system, as well as meet the surface transportation needs of a growing population. Much of the 1990s and the early 2000s saw internal industry growth, as larger companies acquired and merged with smaller producers and multinational ownership appeared. The consolidation of producers continues to this day, with the industry’s largest producers pursuing additional growth through acquisitions and diversification.”

Aggregate production hit an all-time high in 2006 at 3.09 billion metric tons of crushed stone, sand and gravel worth an estimated $21 billion. The workforce at that time was made up of about 121,000 direct employees.

In 2007-08, with the advent of the Great Recession, producers were adversely affected and production fell off sharply as all sectors of the construction industry came, in many areas of the country, to a virtual halt.

Generally, producers kept their heads above water through a lean period between 2007 and 2011. Some producers survived by seeking and finding alternative uses for their products and by downsizing or reducing production cycles.

Further complicating a recovery from the recession was the inability of Congress to come to grips with reauthorizing a long-term surface transportation program that included a fully funded federal highway system.

The years 2009, 2010 and 2011 were flat for the industry, but in 2012 production began inching up again as a slow recovery from the recession began to manifest itself. The industry’s production gains continued year after year until about 2023, when crushed stone and sand and gravel output began to trend downward.

While aggregate volumes have dropped over the last couple of years, many producers continue to make gains within their businesses with strategic price increases and cost management.

Additionally, demand for aggregates isn’t going anywhere anytime soon. With the American Society of Civil Engineers (ASCE) giving the U.S.’s overall infrastructure network a “C” grade in 2025, more materials will be needed in the coming decades if the nation intends to effectively keep up with its aging roads, bridges and highways.

Definition

IIJA: Federal legislation passed in 2021 providing long-term funding for transportation, utilities and infrastructure upgrades.

Sustained investment is the key to providing certainty and ensuring planning goes to development, as well as making larger infrastructure projects attainable. Before recent federal legislation – including 2021’s Infrastructure Investment & Jobs Act (IIJA), many of the U.S.’s infrastructure networks had been neglected for decades at the federal level.

As time passed and investments failed to keep pace with demands, ASCE says the backlog of maintenance projects grew. Meanwhile, demands on infrastructure systems have intensified apart from maintenance.

Community expansion and usage trends, economic growth, unpredictable events and new technologies have called for new plans and project design. These raised stakes require the federal government to continue prioritizing infrastructure investments.

According to ASCE, recent federal and state investments have had a positive impact on U.S. infrastructure. Unfortunately, the full force of increased funding will take years to realize.

Crushed Stone

About 3,400 crushed stone operations are currently present in the U.S. These operations range in size from small – ones reporting production of less than 25,000 tpy – to the handful whose annual production exceeds 5 million tpy.

Among the rock present in quarries throughout the U.S., it is possible to assemble a collection of all the major types in the earth’s crust: old rocks and young rocks; hard rocks and soft rocks; rocks formed under molten pressure and those consolidated from the scrapings of glaciers.

There are rocks consisting of compacted volcanic ash, and rocks laid down on the floors of seas. There are rocks enfolding skeletal remains of microscopic marine organisms, and rocks imprinted with tracks left by dinosaurs. All of these can be found in quarries.

Geologists recognize three basic types of rock: igneous, sedimentary and metamorphic. These differ in their origin, though.

Crushed stone can be made up of igneous, sedimentary or metamorphic rock, although it must be hard and durable enough to meet demanding specifications required of construction materials. In a crushed stone operation, controlled blasts produce a predetermined quantity of rock.

Igneous rocks once existed in a molten state at very high temperatures. They form as molten minerals cool and harden, just as water freezes to become ice. Grains of pure minerals interlock to form the rock. The size of the grains indicates how quickly the rock cooled from a liquid state.

There are two types of igneous rocks: intrusive and extrusive. Intrusive igneous rocks formed slowly within the body of the earth. The most familiar intrusive igneous rock is granite. Extrusive igneous rocks formed quickly on the earth’s surface. Molten rock on the surface is called lava. The mineral grains in this type of rock are generally too small to distinguish with the naked eye.

Sedimentary rocks are formed in a less dramatic way by the weathering and the subsequent layering of minerals. Sands and muds accumulate in great thicknesses, and eventually pressure and chemical cementation turn them into sandstones and mudstones. Sedimentary rocks are not limited erosional material only. Limestone is made from carbonate muds from seawater and carbonate remains of marine organisms.

Metamorphic rocks are formed by any kind of rock – igneous, sedimentary or metamorphic – and altered by high temperature and pressure without remelting. Metamorphism does not change the rock’s bulk chemical composition but does produce new minerals and textures. Marble is a common metamorphic rock that is formed from limestone.

Crushed stone products tend to be extraordinarily heavy, and transporting them to market can be costly. That’s why, on average, crushed stone operations ship no more than 20 to 25 miles from where the product originated. Quarries, as well as sand and gravel operations, often are located near the centers of development they supply.

FULL HANDBOOK

Chapter 1: Industry Overview

Chapter 2: Geology & Site Selection

Chapter 3: Drilling & Blasting

Chapter 4: Excavating & Loading

Chapter 5: Hauling

Chapter 6: Crushing & Hydraulic Breaking

Chapter 7: Screening

Chapter 8: Washing & Classifying

Chapter 9: Conveying & Material Handling

Chapter 10: Loadout & Weighing

Chapter 11: Safety & Health

IN THIS CHAPTER

Use the page numbers to continue reading, or select a section / chapter above.

&uuid=(email))

&uuid=(email))