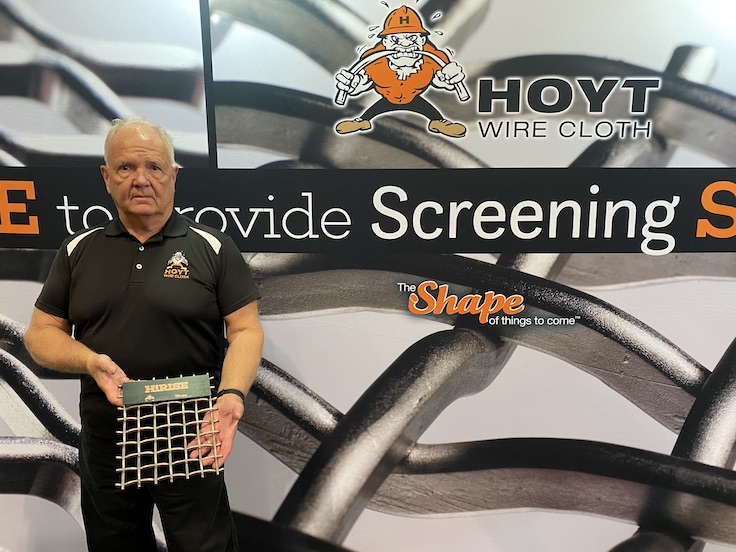

Hoyt Wire Cloth showcased many of its screen media products at AGG1 Aggregates Academy & Expo in Nashville, Tennessee, including its Hi-Rise wire screen.

Jeff Beck, business line manager of Hoyt, says the screen’s design allows for an increased open area, increased wear life and, therefore, increased tons per hour. The Hi-Rise wire is shaped rather than rounded, which Beck says makes all the difference.

“Hi-Rise is different because the wire is shaped, so it is higher than it is wide,” Beck says. “We’ve had cases where we can increase the open area by 12 to 15 percent and see no resulting loss in wear life. In fact, sometimes, we can increase the wear life. We see fines drop out much quicker and fine-size material drops through faster.”

Beck says these improvements were seen in a case study the company did of the Hi-Rise wire in Virginia. And they were seen almost immediately.

“One granite producer in Virginia was able to increase his production of half-inch material from approximately 800 tph to over 950 tph, just by changing to Hi-Rise,” Beck says. “They estimated they paid for the slightly increased cost of the screens in approximately six minutes of running.”