The safety and environmental advantages of dual salt emulsions are gaining attention from the mining sector as companies pursue more ambitious environmental, social and governance goals.

According to Rakhi Pathak, global product manager at BME, dual salt emulsions have proven to be less harmful in terms of potential nitrate contamination and greenhouse gas emissions. At the same time, they can be transported long distances and pumped multiple times before use, while still delivering improved performance benefits – including high energy in a blast.

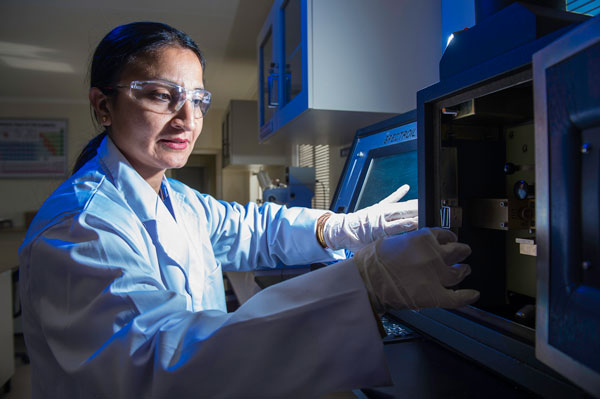

In recent months, Pathak delivered a technical paper at the 7th Drill & Blast Down Under Conference in Australia, where she outlined the concept and constituents of emulsion explosives, its advantages over ammonium nitrate fuel oil, and the different types of emulsions.

“In a single salt emulsion, only ammonium nitrate is used, whereas a dual salt emulsion could contain calcium nitrate or sodium nitrate,” Pathak says. “Urea is an organic compound which is also used in certain applications, such as reactive ground.”

Preventing crystallization

Pathak describes methods of determining the quality of an emulsion through microscopy, where large droplets indicate that the emulsion is aging and showing signs of crystallization.

While ammonium nitrate salt can promote crystallization, the use of calcium nitrate – which has crystals that are more cubic in shape – can reduce the potential for crystallization and considerably extend the life of the emulsion.

Energy conservation

According to Pathak, cold emulsion is manufactured at 65 degrees.

“[That’s] considerably lower than the 85 degrees used for single salt emulsion,” she says. “This has energy-saving benefits, as less heat is required.”

The lower temperature means the emulsion does not require much time for cooling before it can be delivered to customers, providing for an added efficiency benefit in the manufacturing and supply chain processes.

Single salt emulsions produced at higher temperatures require extensive cooling periods, she adds. This limits handling and transportation on demand.

No harmful gases

Mines are also increasingly concerned about harmful gases that could be emitted during blasts. Pathak says a careful balance of the oxidizer (the ammonium nitrate and calcium nitrate) and the fuel in an emulsion is necessary to ensure that only harmless gases are generated.

Where the balance is not optimal, oxides of nitrogen (NOx) fumes can be created. These toxic fumes can affect not just miners, but even communities in the proximity of mines where opencast blasting is conducted.

“The chemical composition of dual salt emulsions can be easily optimized to minimize the generation of harmful gases,” she says.

Less pollution

Another important benefit of dual salt emulsions is in mitigating the risk of nitrate contamination from explosives. Mining companies have become more sensitive to this, BME says, as nitrates can leach into water and land, creating compliance risk in terms of a mine’s environmental impact.

Dual salt emulsions contain much lower levels of nitrate, according to Pathak. This reduces any harmful impact on surface water or groundwater.