Due to the dynamic nature and often continuous operation of belt scales, it is essential to perform at least quarterly checks on several parameters to make sure they provide trouble-free and accurate performance.

Some recommended items to check include:

• Overall system cleanliness, as material buildup will affect zero (tare) and accuracy

• Belt length, to identify any stretching

• The belt tensioning system, to determine if it is still functioning properly with the ability to take up slack

• The belt speed sensing system, to ensure wheels and sensors are clean and functioning properly

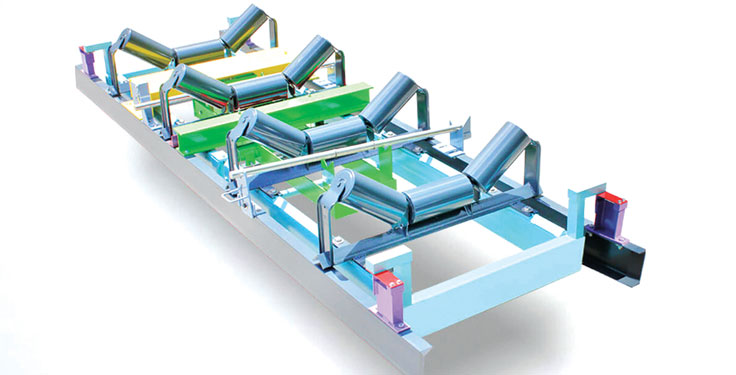

• Conveyor idler condition, particularly cleanliness, alignment and spacing to make sure they’re within factory guidelines

Additionally, scale idlers should be checked for vertical alignment, and they should be cleaned to eliminate any material buildup. Also, are calibrations being performed regularly, and are the results within limits?

Some other considerations to make include running a material test and revalidating k-factors. Make sure Auto Zero (if available) is set up and functioning correctly. Scale components such as flexures, cables and check rods should be inspected and replaced if worn.

Test weights should be inspected and replaced if excessive wear is seen, too.

Related: Developments in aggregate equipment, tech you may have missed

Josh Villano is service manager at Thayer Scale.