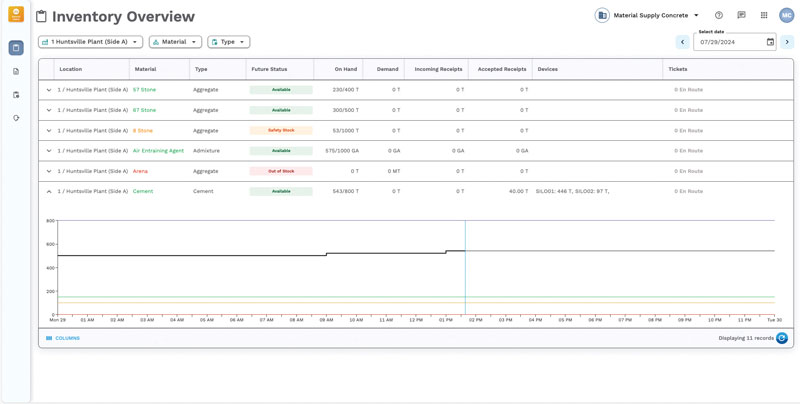

Command Alkon‘s Material Supply is a cloud system that digitally manages raw material receipts and integrates with major batch and dispatch systems. As Command Alkon describes, Material Supply changes the way producers manage their inventories. The system allows users to monitor and update stock levels, coordinate material flows and automate back-office processes. By integrating Command Cloud shared tickets, Command Alkon says suppliers can easily share delivery tickets, reducing the need for manual data entry by plant operators. Customers can also digitize paper tickets using mobile capture or scanners, facilitating a smooth transition to a digital workflow.

Software integrated on loader scales

TAC Insight’s Fast-Weigh software is now integrated with Loadrite loader scales. According to TAC Insight, Fast-Weigh and Loadrite users can now track the status of trucks in-plant and provide operators with information such as customer, product, job and target weights. By integrating with Loadrite scales, TAC Insight says Fast-Weigh eliminates the need for a second device in the loader cab. Fast-Weigh can leverage Loadrite’s platform by sending data directly to the Loadrite 3180 and L5000 loader scales. Additionally, TAC Insight says Fast-Weigh now tracks analytics and performance by comparing Loadrite weights against ticketed weights. Truck turnaround and loading performance can be monitored and reviewed remotely from the Fast-Weigh cloud web portal.

Aligning DOTs with partners throughout the industry

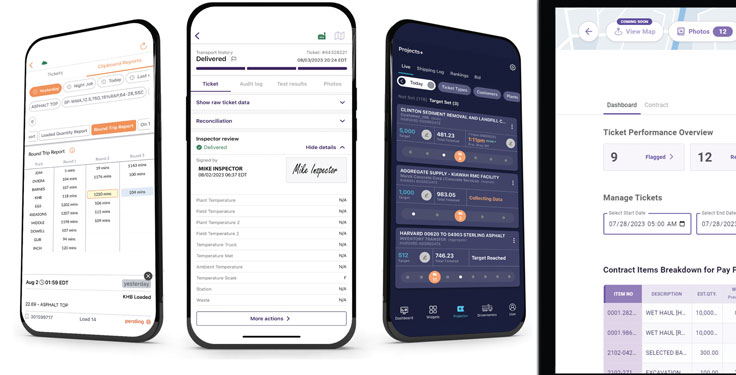

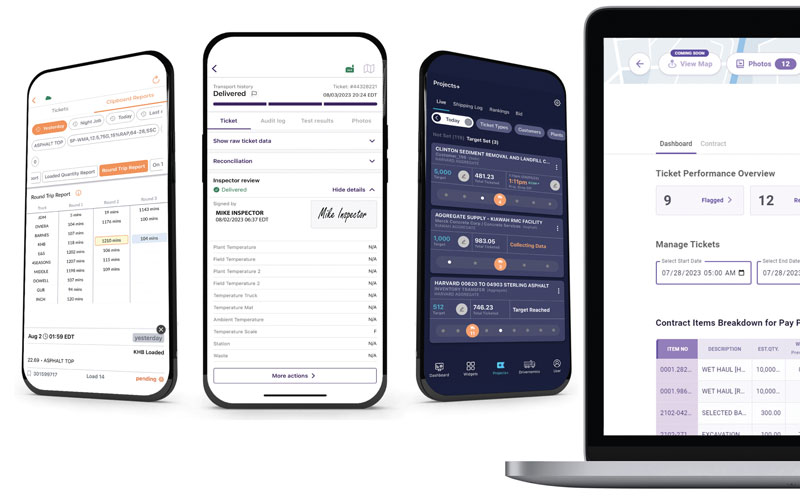

HaulHub’s DOT e-Ticketing software is a comprehensive solution crafted to bring all construction project stakeholders under one unified system of record, simplifying material payments and streamlining operations. According to HaulHub, one digital connection to a material producer’s loadout system allows digital management and materials tracking for construction projects. Effortlessly connecting with any construction material type – be it aggregates, asphalt or ready-mixed concrete – ensures consistent, approved construction material quantities formatted into digital pay requisitions, paving the way for a more seamless and automated inspection process.