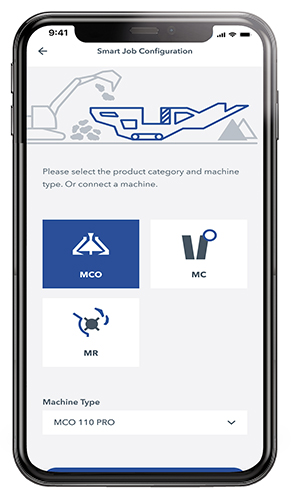

Kleemann’s Spective Connect option, which moves a crusher’s user interface into the mobile equipment housing operators, is now available with a configuration tool.

According to Kleemann, Spective Connect’s smart job configurator helps in the selection of the correct machine settings. To start, operators enter the data of their planned application into the Spective Connect app, which calculates the optimum machine settings automatically. Operators can then transfer the settings to the machine via the Spective touchpanel.

Kleemann says the new tool supports operators in the selection of the best possible crushing tools.

Additionally, the company says all installed optional belt scales can now be displayed in Spective Connect. An overview of live production output is available through a dashboard. Data is recorded in the reporting, allowing conclusions to be drawn about the output and utilization of the plant.

Spective Connect is currently available for the Mobicat MC 120(i) PRO mobile jaw crusher and the Mobicone MCO 110(i) PRO cone crusher.