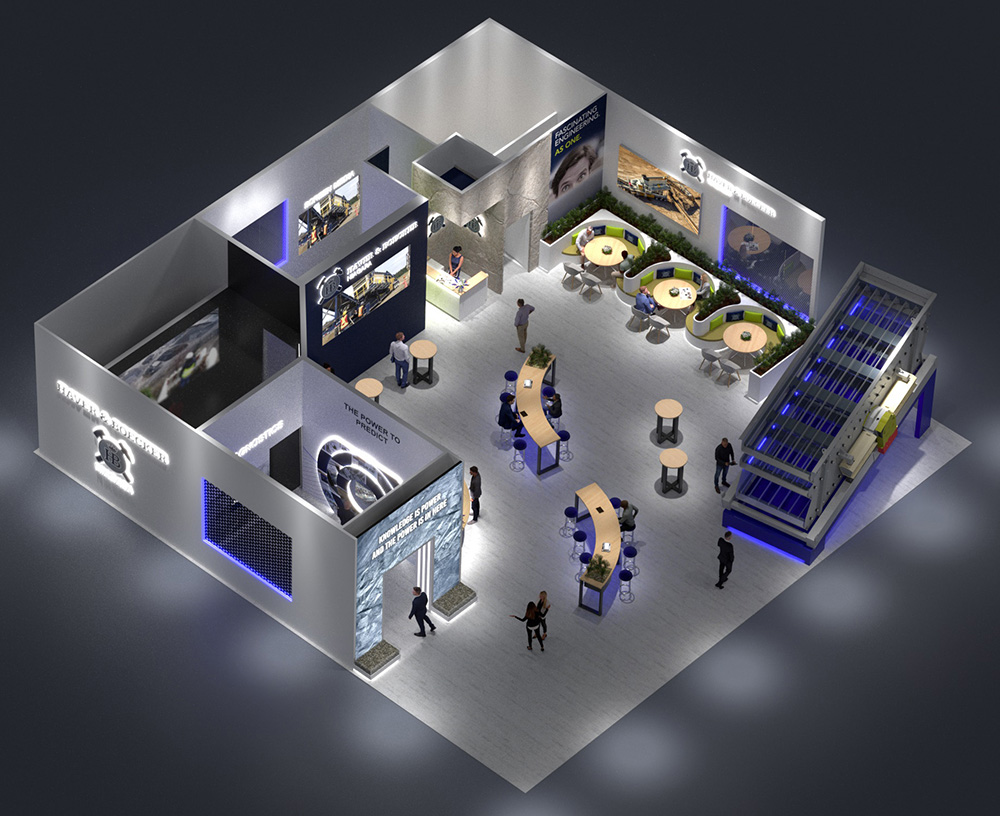

Deister Machine Co. will give ConExpo-Con/Agg showgoers a look at an assortment of screening, scalping and feeding solutions at the March 3-7 Las Vegas trade show.

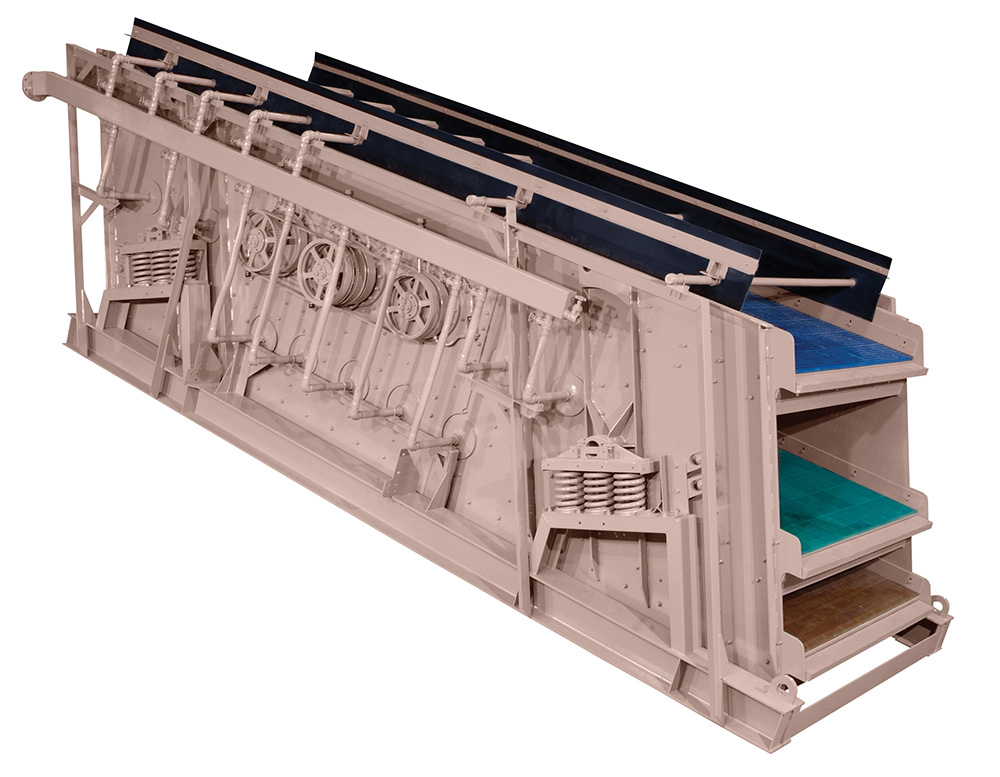

Exhibiting in the Las Vegas Convention Center’s Central Hall (Booth C30973), Deister will give attendees an up-close look at its super-duty BHM-3824. Deister says the inclined, three-deck, 8-ft. x 24-ft. screen features a triple-shaft vibrating mechanism that optimizes material stratification and minimizes blinding – all while delivering accurate sizing and higher throughput.

The vibrating mechanism is located between the decks, Deister says, reducing overall height and making the BHM ideal for retrofits or space-restricted applications.

Additionally, Deister will feature its vibrating grizzly feeder, which combines scalping and feeding in one solution. Typically mounted under a hopper or bin, Deister says the feeder prevents material from bridging in the hopper while eliminating surges in loads to the crusher. The result is a continuous, uniform material feed that boosts crusher utilization and capacity.

The company will also highlight its EMCO 360 crusher optimizer feeder, which optimizes cone crusher performance. With a 360-degree discharge opening, the unit distributes a homogeneous feed to the cone to keep cone crushers choke-fed for optimum efficiency, greater manganese wear life, improved production rates and the consistent yield of a more cubical product.

Related: Check out P&Q’s full coverage of ConExpo-Con/Agg 2026