HD Hyundai Construction Equipment North America expanded its HX crawler excavator product line with two new large-frame mass excavators. According to Hyundai, the 82-ton HX800A L and the 100-ton HX1000A L are designed to meet the needs of high-volume earthmoving, mining and quarrying applications. The HX800A L has a 528-net-hp engine while the HX1000A L is equipped with a 620-net-hp engine. Each machine can be configured with various boom and arm configurations to match the material being excavated. As Hyundai describes, both new excavator models offer selectable power modes and an electronic power-optimizing system for control over machine power and efficiency.

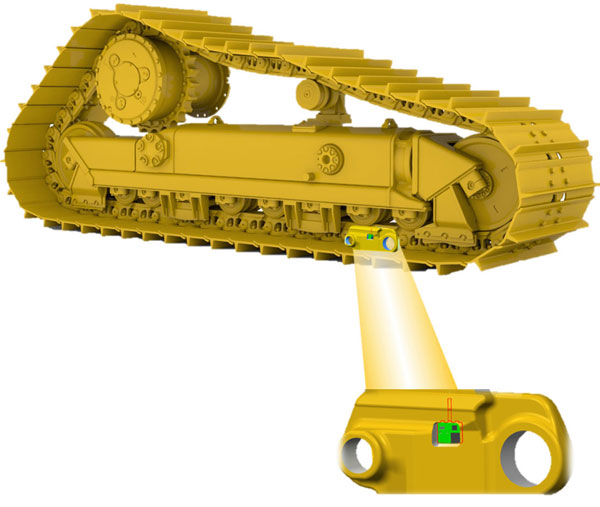

Technology senses wear on tracks

Caterpillar debuted a wear sensor for tracks so customers can remotely monitor undercarriage wear to better predict wear, plan maintenance and increase machine uptime. The new Cat Track Wear Sensor (CTWS) is part of the Cat Wear Management System, wirelessly communicating track link wear information from the machine to dealers for monitoring. The company says timed alert intervals improve inspection scheduling while streamlining replacement parts ordering. The real-time track wear status function enables no-touch track link measurements, Caterpillar says, increasing fleet coverage by automating inspections, providing visibility to track wear when operating in remote locations, and allowing for prioritized timing of service visits by helping to optimize manual inspections.

New line of drill string components debuts

Epiroc launched the ET line of drill string components, which includes the ET66, ET45 and ET38. Developed over five years, Epiroc says the new drill strings provide enhanced tophammer drilling efficiency and reliability. The line of drill strings is stronger and stiffer than previous versions, the company adds, and it minimizes unplanned stops due to drill string failure. Additionally, the tube’s shoulder drive can transfer more energy into the rock, reducing vibration in the drill string and rig.

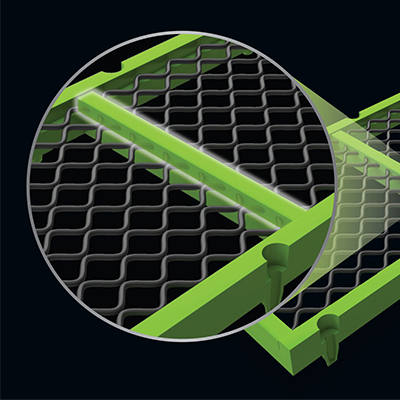

Updated impact cradle offers added durability

Superior Industries unveiled a redesigned conveyor impact cradle, with a new arrangement that includes larger pad cartridges to enhance durability and a reinforced point of connection between the pads and cradle frame. According to Superior, its new conveyor impact cradle is a modern redesign of the traditional impact bed. While both products absorb the force of falling material to prevent damage to conveyor belts, Superior says its impact cradle is engineered to address common shortcomings associated with the design of traditional impact beds. Superior’s design, for example, features a curved bed that supports belting, leaving no gaps to trap fugitive material. Also, Superior says pads are easy to slide on or off the cradle frame in tight, hard-to-access transition zones.